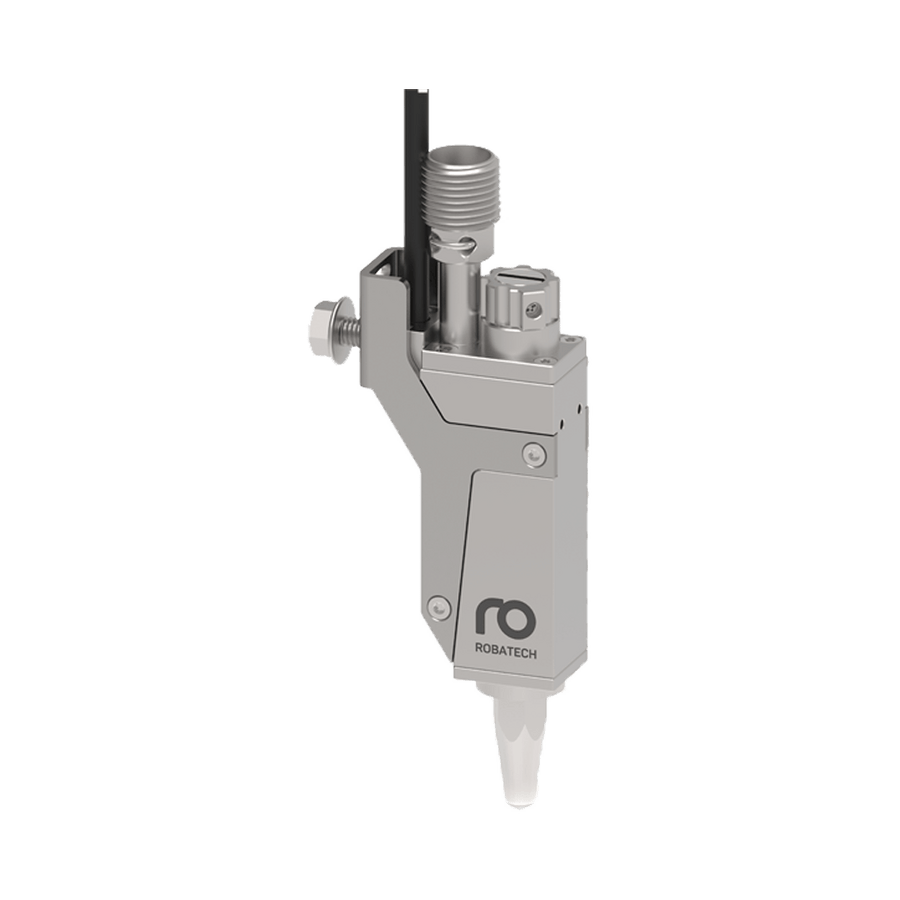

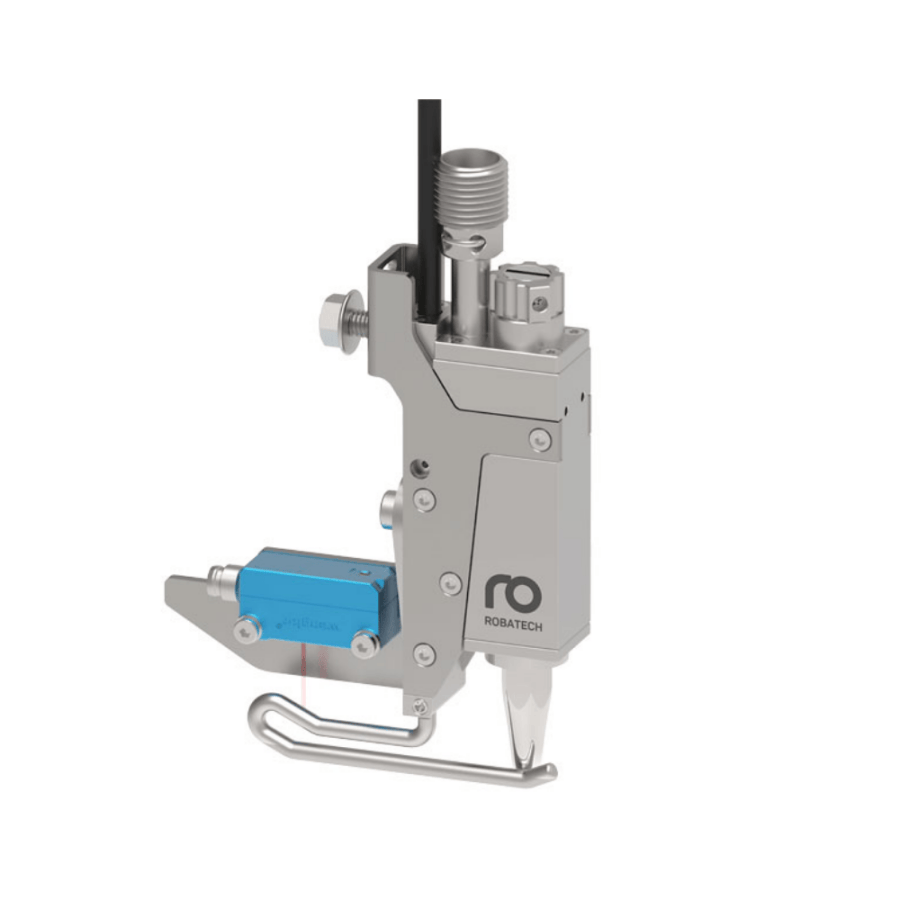

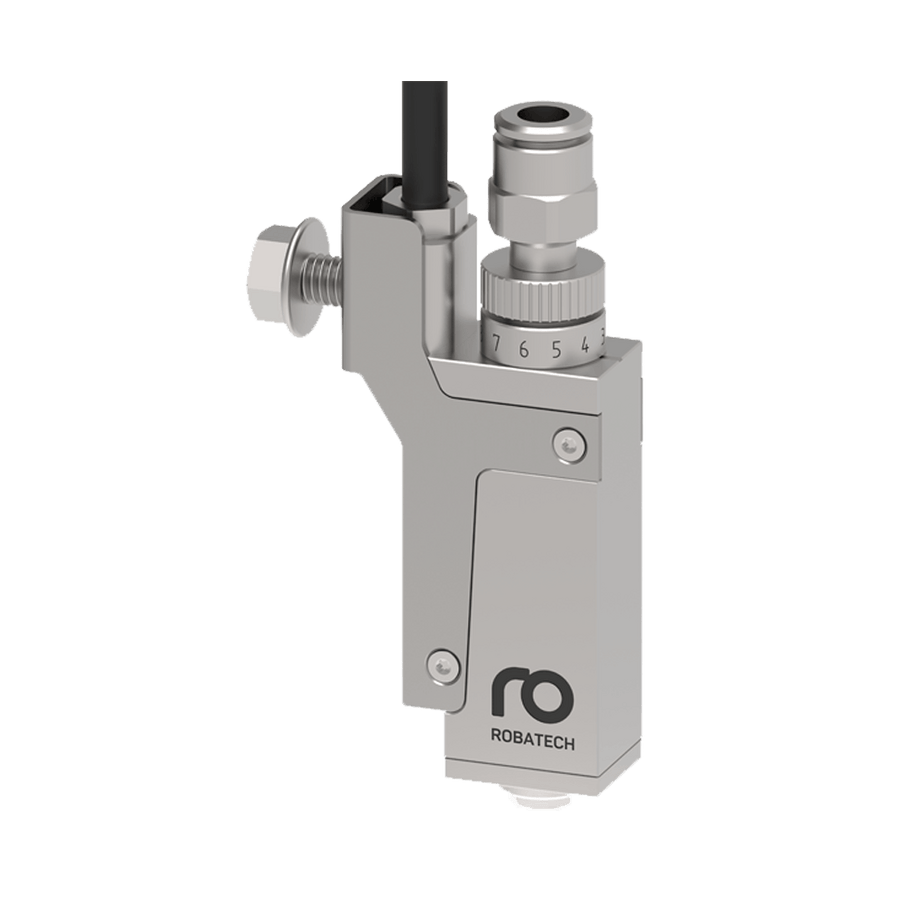

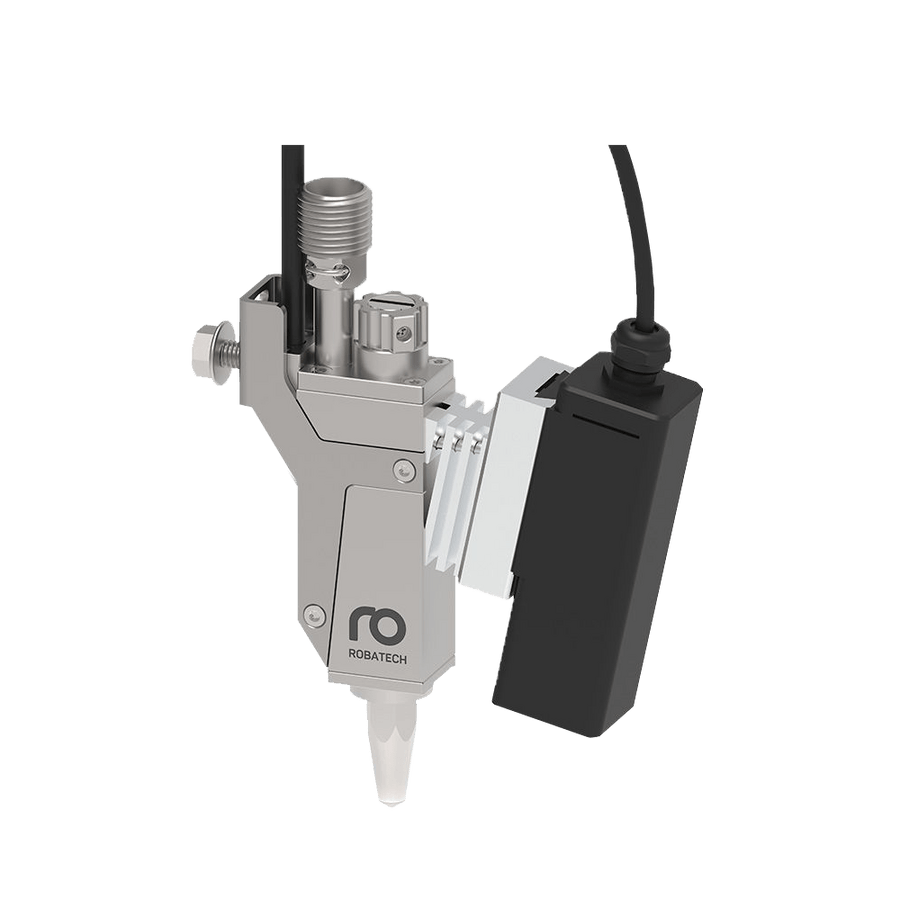

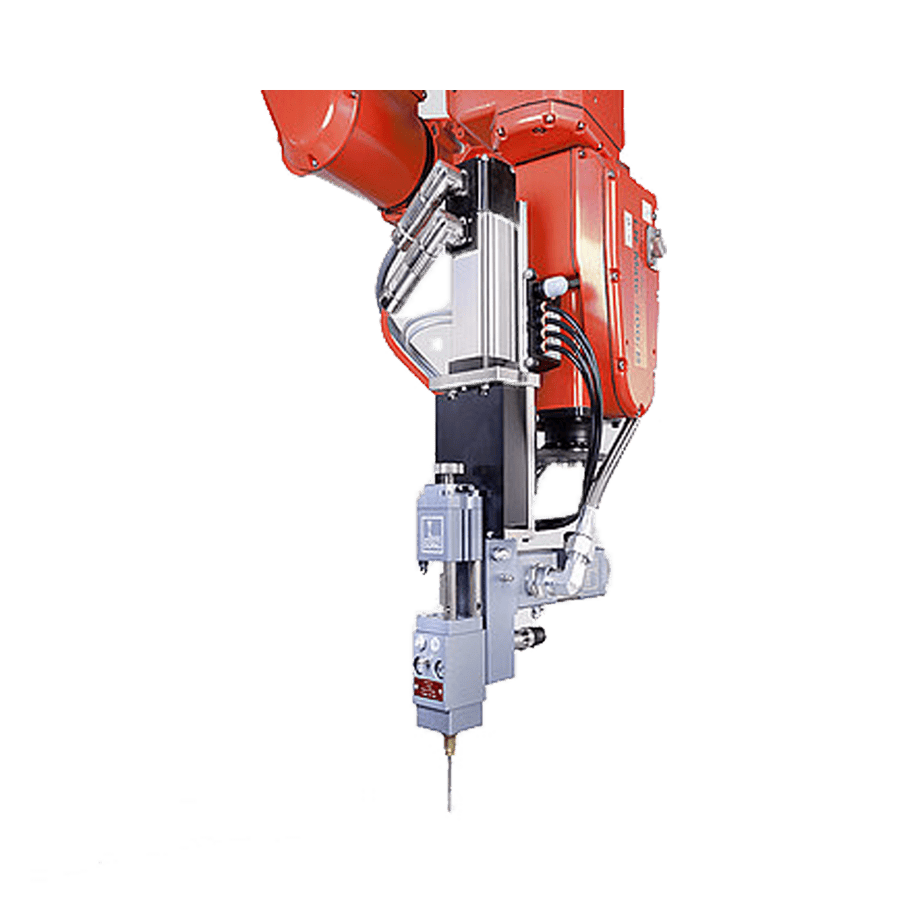

Coredis is used for the processing of special low density 1K epoxies filled with micro hollow spheres. The unique challenge in this case is that we are dealing with a reactive medium which remains in the material contacting systems after processing and could be subjected to a curing reaction. In order to prevent this, coredis features a specially developed structure. The material is supplied directly from the delivery container and the metering is carried out by means of a gear pump mounted on a heated follower plate. The material is guided through the connected heater hose to the dispending nozzle which continuously fills the core filler into the honeycombs.

In case of production interruptions, all material contacting parts including the container can be dismounted in a few minutes and stored in a cold storage. Thus, no cleaning is required. If the production is restarted, the application can be resumed due to the heated components. This unique structure allows for the first time the continuous as well as precise metering of 1K core fillers and has the advantage that, after a simple expansion of the system, various materials can be processed on the same system.