| TECHNICAL DATA | ||

|---|---|---|

| Temperature range | 20 to 185°C | |

| Adhesive pressure | Max. 75 bar | |

| Adhesive | Thermoplastic adhesives | |

| Adhesive viscosity | 100 to 2,500 mPas | |

| Operating cycles | 500 million * | |

| Switching frequency | 80 Hz */** | |

| Adhesive outlet | 0.5 ms * | |

| Jetting element width | 18 mm | |

| Nozzles | 196 Diamond | |

| Supply voltage | 230 VAC (EN60204), 50/60 Hz | |

| Control signal | 24 VDC / 8W | |

| Attachment | For shaft Ø12 mm, flat steel or M5 thread | |

| Sound pressure level | Approx. 35 dB (A) | |

| Degree of protection | IP55 | |

| Installation dimensions (mm) | 132.3 x 24 x 139.6 | |

| * Depending on operating envitonment and conditions (adhesive, temperature, frequency, etc.) | ||

| ** Continuous load maximum 10 Hz, double head = 25 Hz, quad head = 15 Hz | ||

PRODUCT

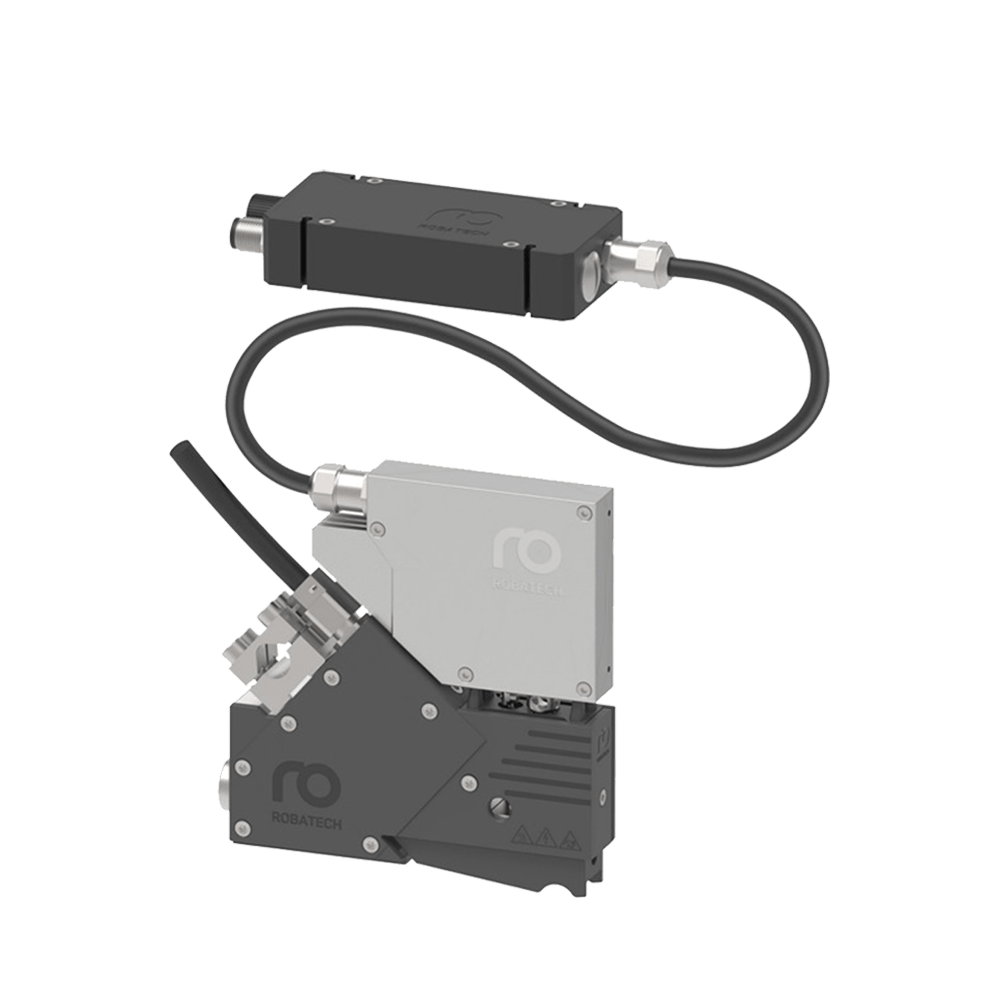

Speed Star

Speed Star

An ultra highspeed with reliable performance and longer lifetime, based on electric structure foundation

SpeedStar Diamond jetting heads are characterized by fast, precise adhesive application of beads and dots and very high durability. It is designed for extremely short switching cycles with small and precise adhesive dots in processes with very high speeds. Thanks to the narrow design of the SpeedStar modules, the jetting heads are available in multiple-module versions. One of the most advantages is that the SpeedStar Diamond jetting heads operate with 24 VDC and can be directly actuated via a PLC.

SpeedStar Diamond application heads reach a very high service life thanks to their high quality. The repeatability is unique, resulting in a consistent dot size and positioning without manual recalibration across the entire service life. Thanks to the integrated filter in the heating block, nozzle blockage is prevented. The jetting heads are electromechanical and do not require compressed air.

Share

Skip to content

Skip to content