| TECHNICAL DATE | |

|---|---|

| Adhesive type | Granulate and pastilles |

| Granulate size | Max. Ø12mm |

| Pastilles size | 12 x 12 mm |

| Feed capacity* | 4 kg per minute |

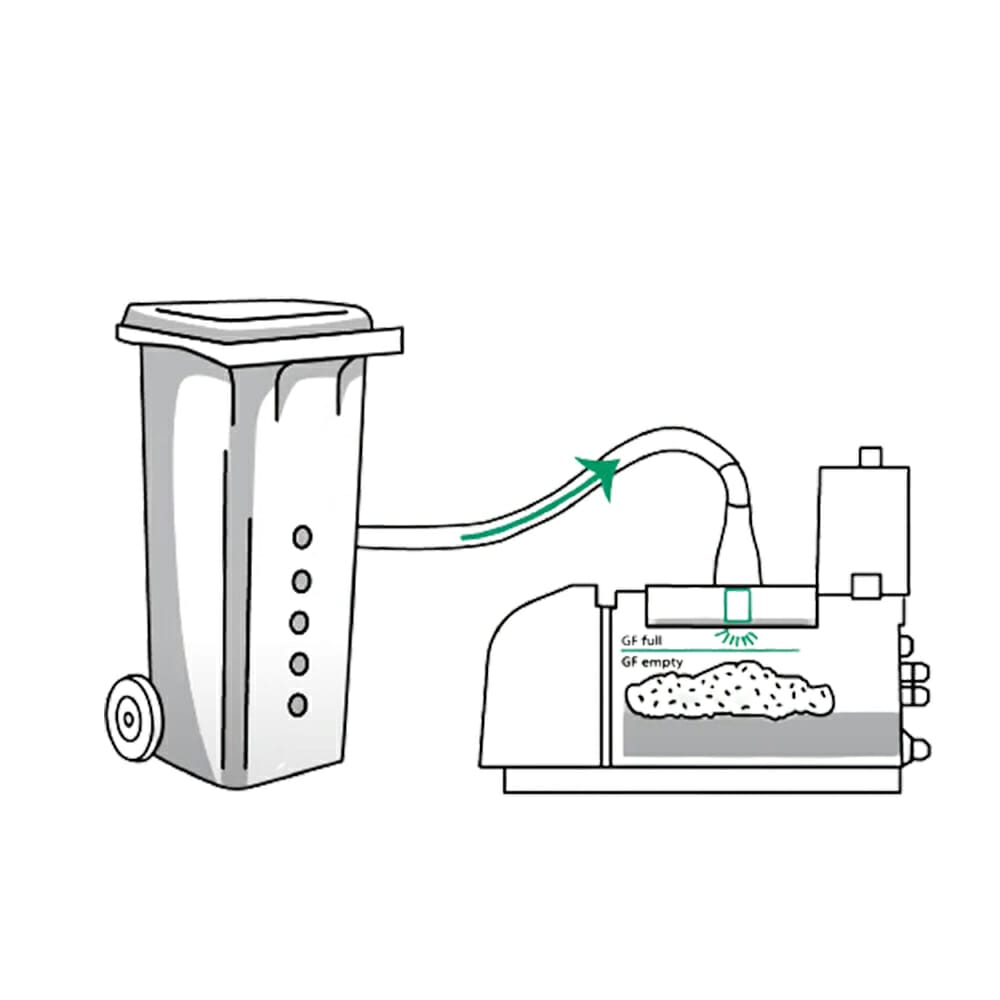

| Container sizes | S: 10 iters / M: 50 liters / L: 100 liters |

| Suction unit | S: 1 / M: 1 or 2 / L: 1 or 2 |

| Feeding distances | Horizontal max. 7.5 m, vertical max. 2.5 m |

| Compressed air connection | 6 bar, dry, filtered, unoiled, G1/4″ connection |

| Compessed air consumption at 6 bar | max. 250 standard liters/min. |

| Electrical connection | Robatech systems: 24 Volt DC from the system |

| *Function and feeding capacity depend on quality, size, shape, and stickiness of the adhesive | |

Experience in the industrial field of more than 40 years, we do not want to be just your supplier, but rather, we want to be your perfect partner to share the experience together

SOUTHERN SUPPLY CO., LTD.

- 442 Sukhonthasawat Rd., LatPhrao Bangkok 10230

- E-Mail : sales@soutthern-supply.net

- Tel : 02-5788490 - 4

- Fax : 02-5531233