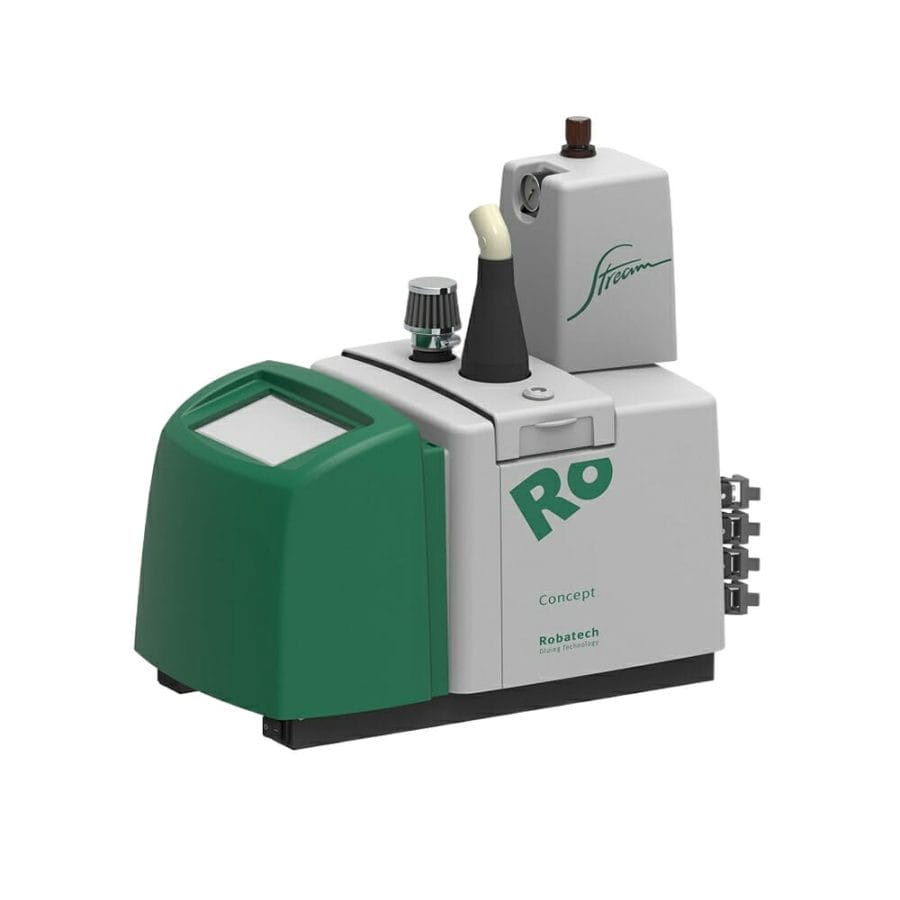

| Technical Data | |||

|---|---|---|---|

| Container size | Ø 120 up to 128 mm, height 160 to 200 mm | ||

| Ø 144 up to 148 mm, height 130 to 200 mm | |||

| Melting capacity | max. 10 kg/h at 10,000 mPas (With 2-block magazine) with PUR adhesives | ||

| max. 8 kg/h at 100,000 mPas (With 2-block magazine) with PUR adhesives | |||

| max. 10 kg/h at 10,000 mPas (With 1-block magazine and press) with PUR adhesives | |||

| max. 10 kg/h at 65,000 mPas (With EVA granlate) | |||

| Number of delivery pump | 1 | ||

| Gear punps | GPR 12 I ZPR 2 I ZPR 12 I ZP 2 I ZP 3 | ||

| Delivery volumes | GPR 12: max. 9 kg/h I ZPR2:max 1.7 kg/h I ZPR 12: max. 12 kg/h | ||

| ZP 1: max. 25 kg/h ZP 2: max. 52 kg/h I ZP 3: max. 50 kg/h | |||

| Adhesive viscosity | GPR 12: 2,500 to 120,000 mPas I ZPR 2: 500 to 120,000 mPas | ||

| ZPR 12:500 to 120,000 mPas I ZP 1: 1,000 to 65,000 mPas | |||

| ZP 2: 1,000 to 65,000 mPas I ZP 3: 1,000 to 10,000 mPas | |||

| Operating temperature | 20 to 210°C or 68 to 410°F / accuracy ± 0.5°C | ||

| Hydraulic heated hose connections | 2 G 1/2″ adhesive outlets and 1 bursting screw | ||

| Supply voltage | 230 / 400 V AC, 50/ 60Hz 3LNPE, 16 A standard Europe | ||

| 400 V AC 50 / 60Hz 3LPE, 16 A with neutral point generator | |||

| 200 – 240 V AC, 3ØPE, 32A, standard USA-JAPAN | |||

| Weight | Approx. 80 kg | ||

| Compressed air supply | min. 5 bar, oil-free air class 4 according to DIN ISO 8573-1 | ||

| * Reference value, de[emds on adhesives and conditions | |||

Experience in the industrial field of more than 40 years, we do not want to be just your supplier, but rather, we want to be your perfect partner to share the experience together

SOUTHERN SUPPLY CO., LTD.

- 442 Sukhonthasawat Rd., LatPhrao Bangkok 10230

- E-Mail : sales@soutthern-supply.net

- Tel : 02-5788490 - 4

- Fax : 02-5531233