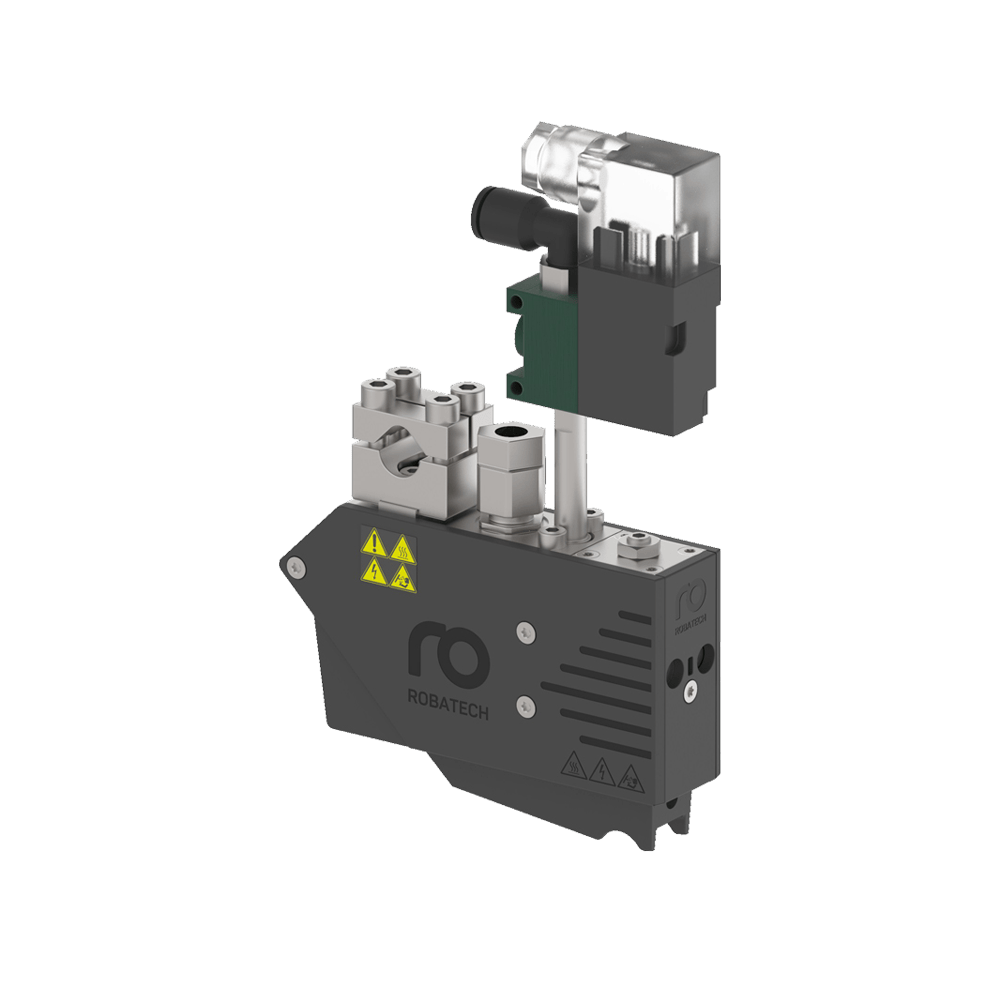

| TECHNICAL DATA | ||

|---|---|---|

| Temperature range | 20 to 200°C | |

| Adhesive pressure | Max 100 bar | |

| Adhesive | Thermoplastic adhesives | |

| Adhesive viscosity | 100 to 5,000 mPas | |

| Operating cycles | 10 million * | |

| Switching frequency | 50 Hz */** | |

| Adhesive outlet | 12.5 ms * | |

| Jetting element width | 22 mm | |

| Nozzles | 294 / 296 / 292 (90°C) | |

| Air connection | 5 to 6 bar, cleaned and not oiled | |

| Air consumption | Approx. 6 ml per jetting element / cycle (5 bar) | |

| Supply voltage | 230 VAC (EN60204), 50/60 Hz | |

| Supply voltage, solenoid valve | 24 VDC / 7.3 W | |

| Attachment | For shaft Ø12 mm, flat steel or M5 thread | |

| Noise level | Approx. 65 to 70 dB (A) | |

| Degree of protection | IP55 | |

| * For jetting element and valve. Depending on operating envitonment and conditions (adhesive, temperature, frequency, etc.) | ||

| ** Continuous load maximum 10 Hz | ||

Experience in the industrial field of more than 40 years, we do not want to be just your supplier, but rather, we want to be your perfect partner to share the experience together

SOUTHERN SUPPLY CO., LTD.

- 442 Sukhonthasawat Rd., LatPhrao Bangkok 10230

- E-Mail : sales@soutthern-supply.net

- Tel : 02-5788490 - 4

- Fax : 02-5531233