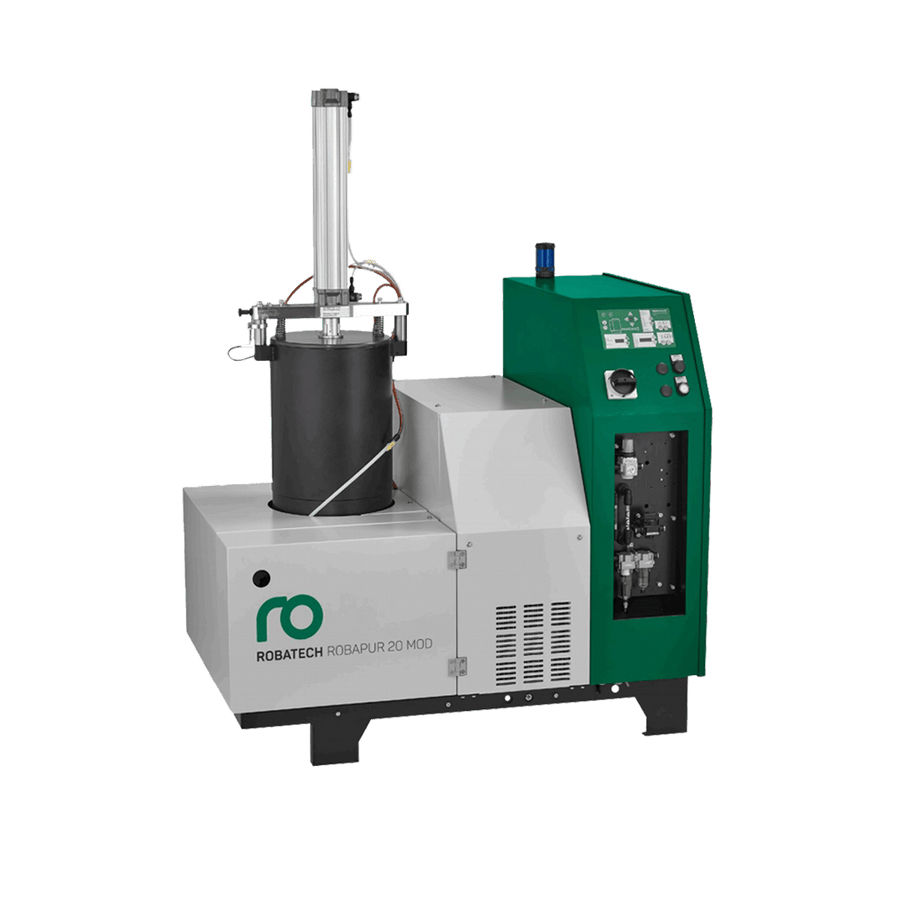

| Technical Data | JumboFlex 50 | JumboFlex 100 | |

|---|---|---|---|

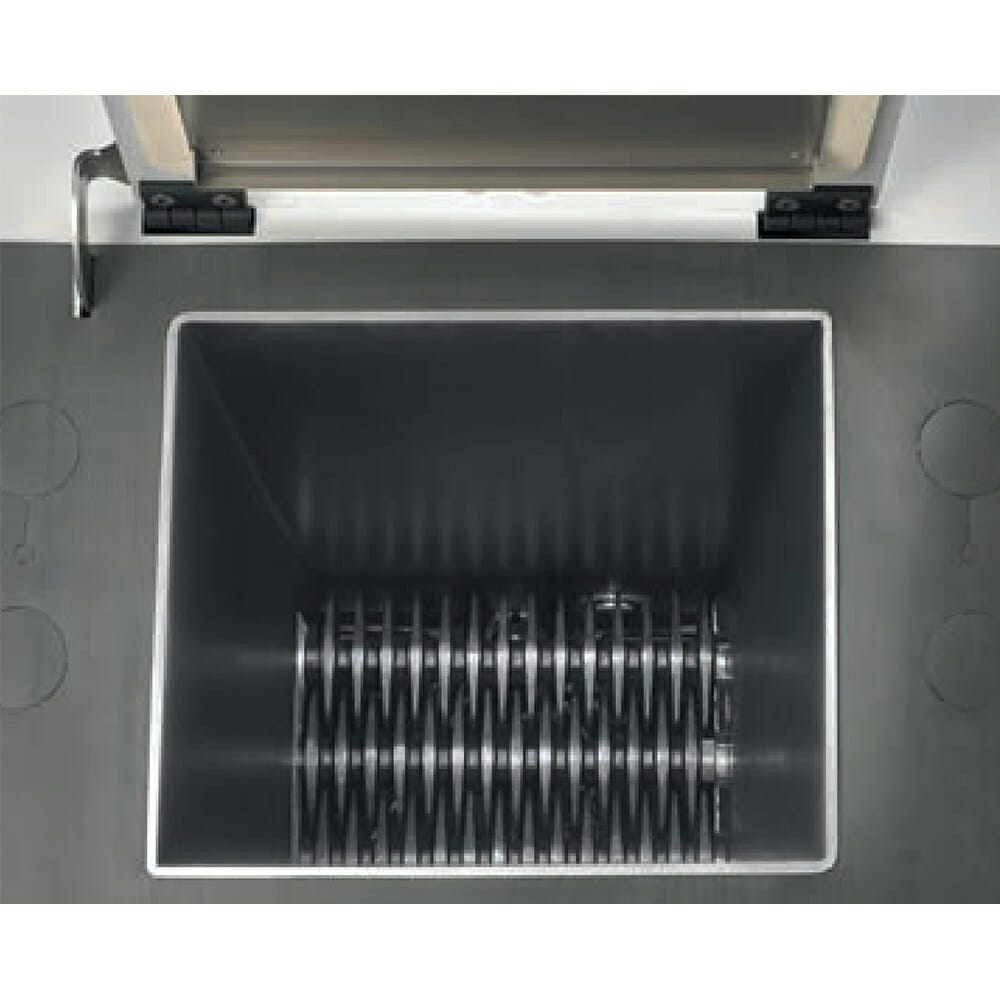

| Supply tank | 50 dm3 | 100 dm3 | |

| Melt rate* | 50 kg/h | 100 kg/h | |

| Adhesive viscosity | ZP = 1’00 to 65’000 mPas | ||

| GP = 2’500 to 65’000 mPas | |||

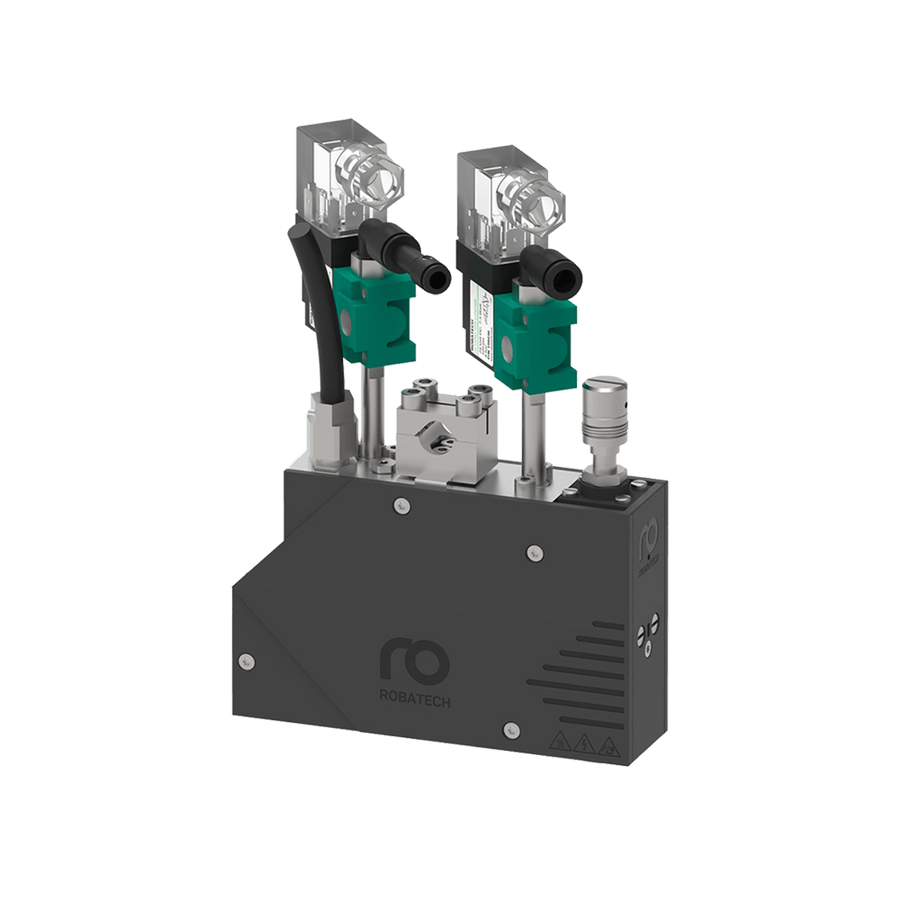

| Number of pumps | 1 to 2 | ||

| Feed capacity** | ZP1: 1,5 to 21,9 kg/h, ZP2: 2,9 to 44,1 kg/h | ||

| ZP3: 5,9 to 89,0 kg/h, ZP4: 11,9 to 177,9 kg/h | |||

| Operating temperature | 20 to 200°C | ||

| Number of heated hoses | 2 drilled holes per pump G 3/4″ | ||

| Supply votage (EU) | 400 / 230V , 3Ø N/PE, 50/60 Hz | ||

| 400 V, 3Ø PE, 50/60 Hz | |||

| Supply votage (USA, JP) | 200 – 240 V,3Ø PE, 50/60 Hz | ||

| Dimensions (width x depth x height) | 850 x 760 x 1300 mm | ||

| Weight (1-pump device) | 245 kg | 280 Kg | |

| * The melt rate varise depending on the adhesive type which is porcessed with the device | |||

| ** Data applies for 50 Hz, efficiency = 85 % and density = 1. The feed capacity varies depending on adhesive type | |||

Experience in the industrial field of more than 40 years, we do not want to be just your supplier, but rather, we want to be your perfect partner to share the experience together

SOUTHERN SUPPLY CO., LTD.

- 442 Sukhonthasawat Rd., LatPhrao Bangkok 10230

- E-Mail : sales@soutthern-supply.net

- Tel : 02-5788490 - 4

- Fax : 02-5531233