| Technical data | PUR Premelter RobaPress |

|---|---|

| Block size | 2 kh blocks of adhesive without inliner Ø 120…129mm, length max. 155 mm |

| Adhesive viscosity | 100…60’000 mPas at processing temperature |

| Temperature range | 20…170°C |

| Melting temperature | see data sheet of the adhesive producer |

| Lowering temperature | approx. 70°C below working temperature |

| Melting Capacity | Max. 6kg/h (depending on adhesive) |

| Operating voltage | 400 / 230 Volt 50/60 Hz 3 LNPE

230 Volt 50/60 Hz 1 LNPE |

| Fuse protection | 16AT (slow) |

| Heating capacity | 16000 Watt |

| Compressed air supply | 6 bar, air free of oil, min. class 4, ISO 8573-1 |

| Control | Robatech controller with CLS electronics |

| Ambient temperature | 0…50°C |

| Relative air humidity | < 90 %, not condensating |

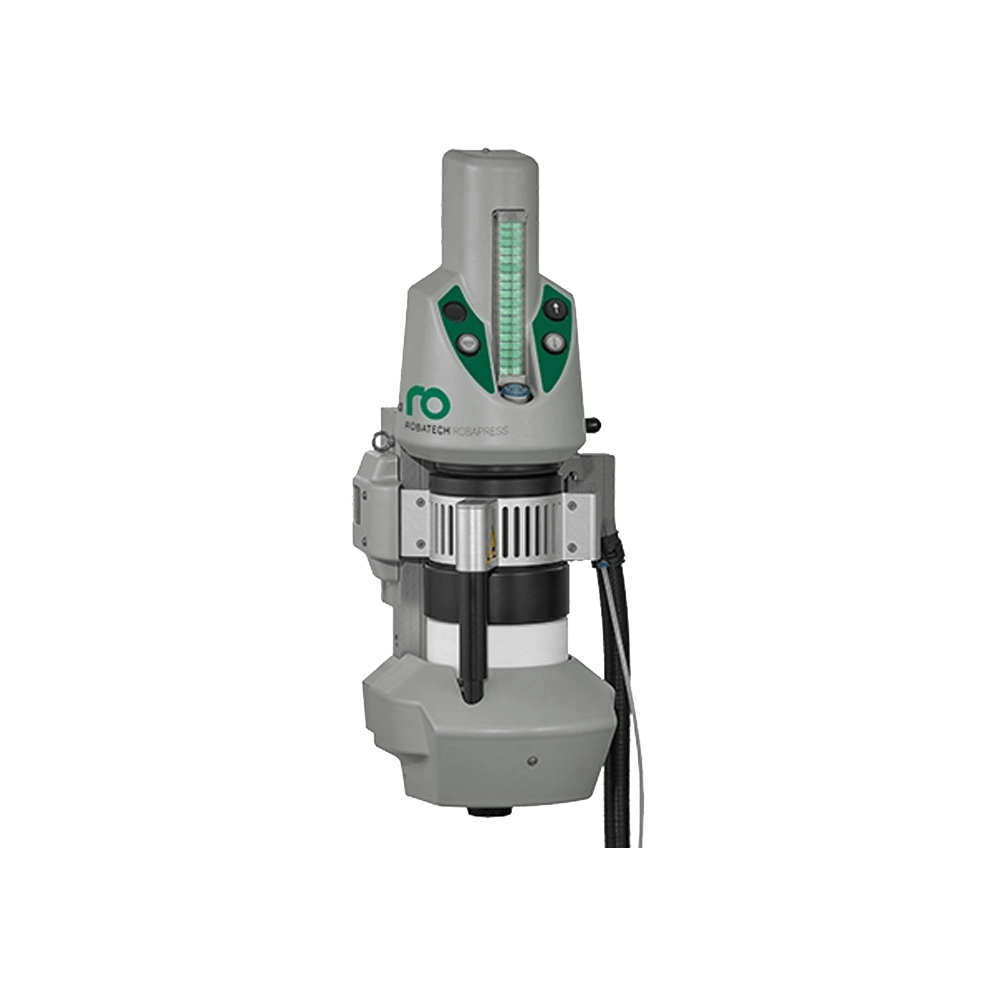

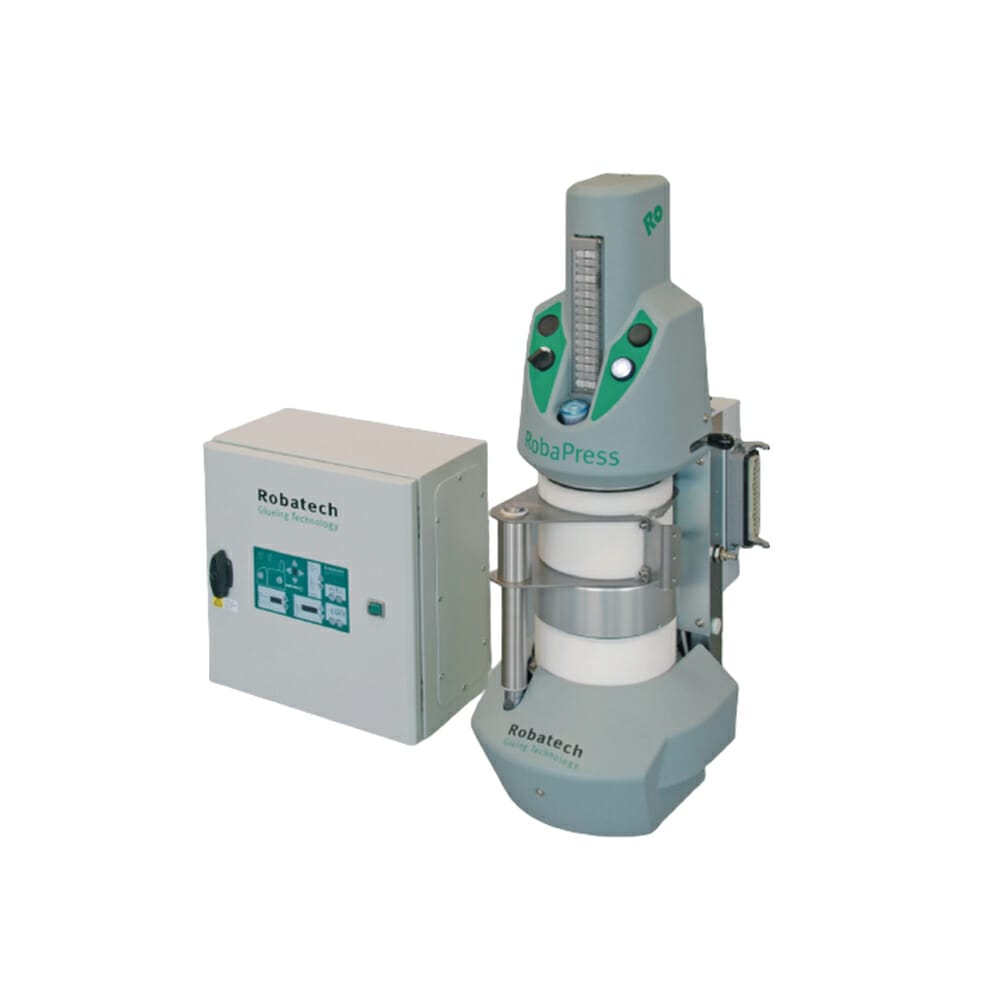

PRODUCT

Roba Press

Roba Press

Roba Press is a ‘Melt on Demand’ system used to melt blocks of PUR hot melt. The 2–3 kg blocks of PUR are in airtight containers and melted gently depending on demand. This produces no waste.

The block melter is used to fill glue tanks on edge banding machines, automatic book binding machines, etc., with PUR hotmelt. The appliance serves to melt polyurethane hotmelt which must not come into contact with the ambient air during storage and conditioning for processing.

After the appliance is switched on, it is heated to the defined readiness temperature. If the fill level in the glue tank is too low, the block melter is heated to the programmed operating temperature. As soon as this higher temperature is reached, the cover slide opens and the pressing cylinder presses the PUR block onto the melting grate. The contact pressing and melting process lasts until the glue tank is full again. In the interest of gentle handling of the PUR adhesive the appliance’s temperature is reduced to the readiness value again as soon as the glue tank is full. The pressing cylinder stops immediately after filling and the cover slide closes again to ensure that no ambient air reaches the block of PUR

RobaPress is suitable as a premelter for edge–banding machines, spine binding systems and other PUR roller application systems.

- Integrated buffer prevents burn through

- Easy operation and maintenance.

- Melting on demand

- No unneeded temperature stress

- Easy filling of glue tanks with PUR

Share

Skip to content

Skip to content