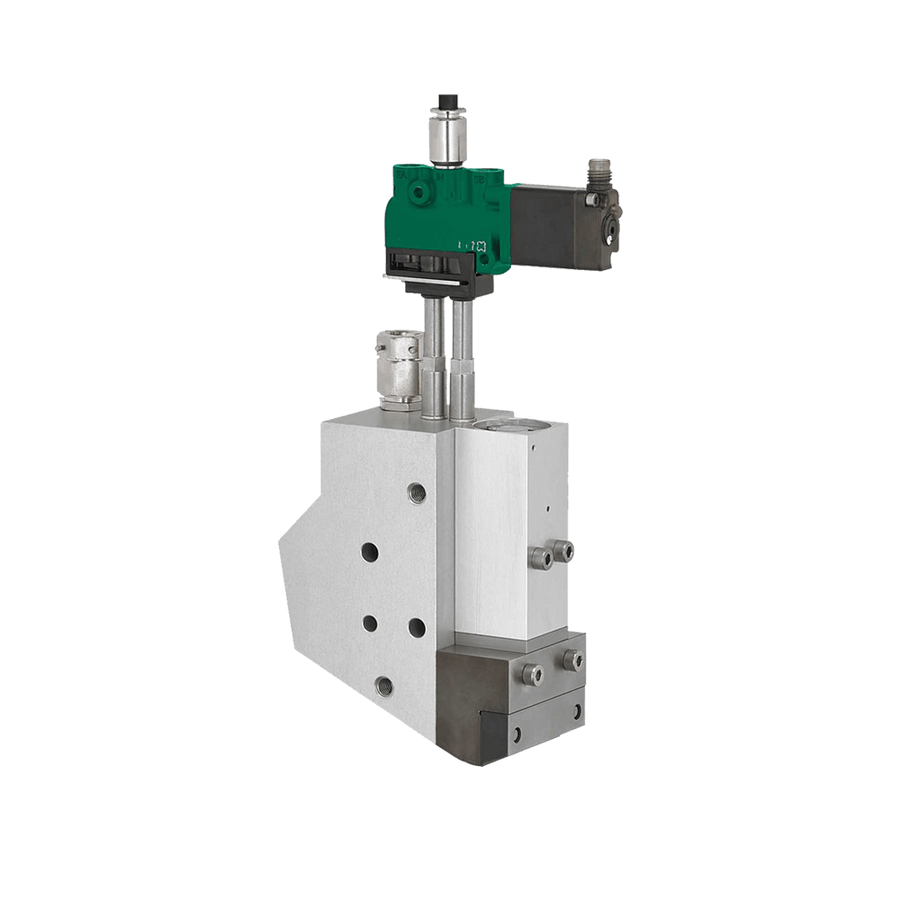

Pneumatic lifting cylinders lift and lower the melting plate. For safety reasons, two-hand control device is required for moving the melting plate. Once the operating temperature is reached, the plate is pressed onto the drum content. This results in melting of the adhesive surface. Next, a pump delivers the melted material for further processing to the pump block outlet. An overpressure valve limit the maximum system pressure to 100 bar.

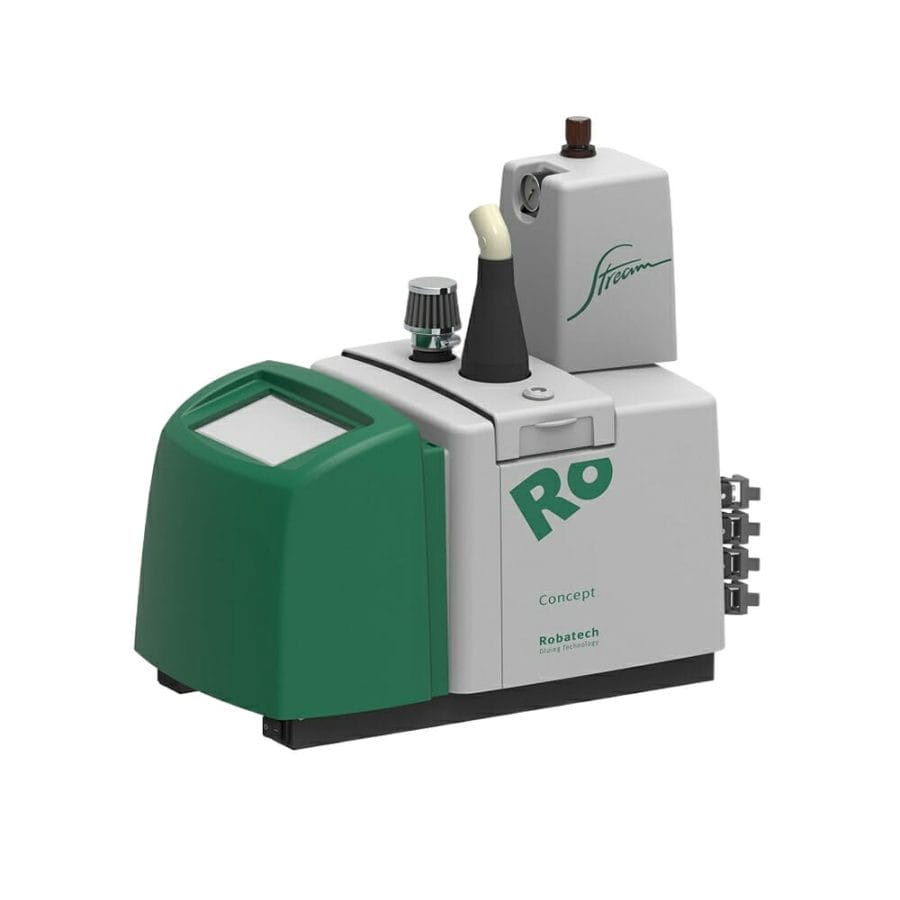

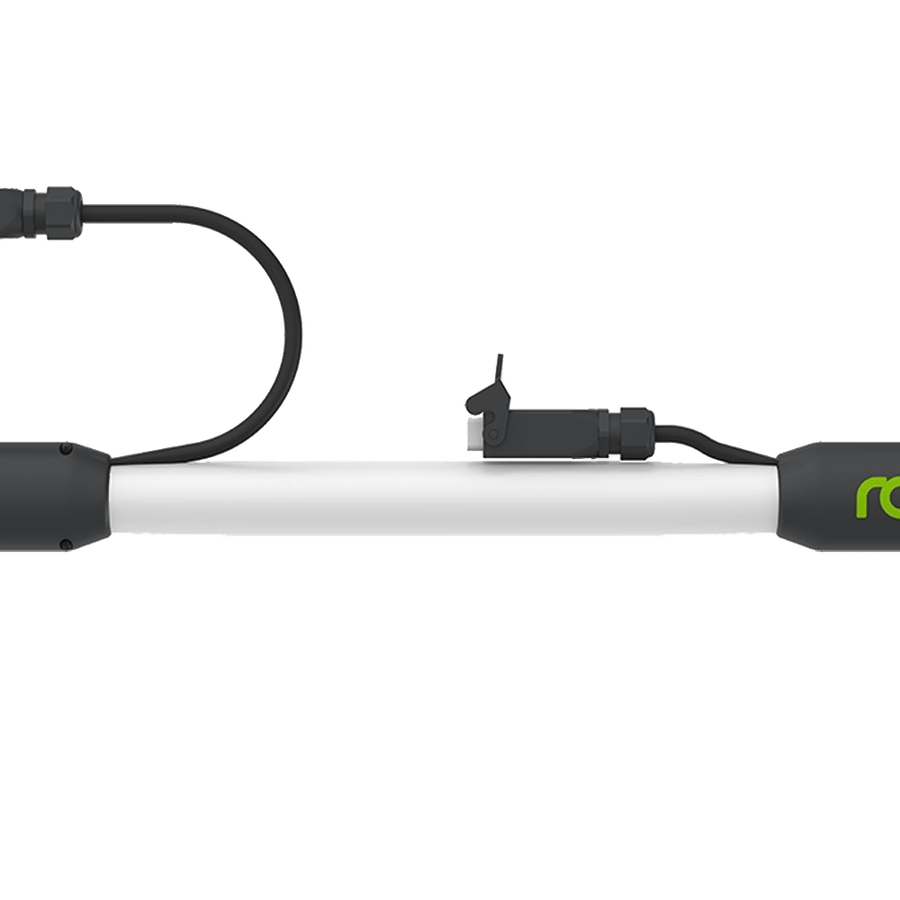

RobaDrum 200 is ideally suited for melting inserts with high adhesive flow. The drum melter is designed for processing and delivery of thermoplastic adhesives, PUR hot melt adhesives, or sealants in different production processes. To ensure a reliable production process, RobaDrum 200 is additionally equipped with the user-friendly RobaVis touchscreen. The intuitively controllable user-interface offers various functions like the measurement of the power consumption for a controlled and sustainable production as well as the “help-texts” which additionally support the operator. The factory data software InfoPlus permanently records data of the adhesive application system, creates a log, calculates consumption data and generate messages for a preventive maintenance.