| TECHNICAL DATA | ||

|---|---|---|

| Temperature range | 20 to 200°C | |

| Adhesive pressure | Maximum 100 bar | |

| Adhesive | Thermoplastic adhesives | |

| Adhesive viscosity | 100 to 10,000 mPas * | |

| Switching frequency | 125 Hz ** | |

| Application width | FK IT 25: 3-25 mm / FK IT 50: 25-50 mm / FK IT 75: 50-75 mm | |

| FK IT 100: 75-100 mm / FK IT 125: 100-125 mm | ||

| Minimum coating time | 4 ms *** | |

| Minimum gap | 4 ms *** | |

| Supply voltage, solenoid vale | 24 VAC, 8.0 W | |

| Air connection solenoid valve | 5 to 6 bar, cleaned and unoiled | |

| Air consumption | Approx. 8 ml per jetting element / cycle (5 bar) | |

| Attachment | For RO mounting bracket with 2x M6 on the left and right side | |

| Noise level | Approx. 65 to 70 dB (A) | |

| Degree of protection | IP40 | |

| * Function test required if adhesives with higher viscosity are used. | ||

| ** Depending on adhesive, viscosity, temperature, frequency, pressure, air quality and stroke. Continuous load maximum 125 Hz | ||

| *** Depending on adhesive, viscosity, temperature, frequency, pressure, air quality and stroke. Jetting element (factory settings: 0.6 mm). | ||

PRODUCT

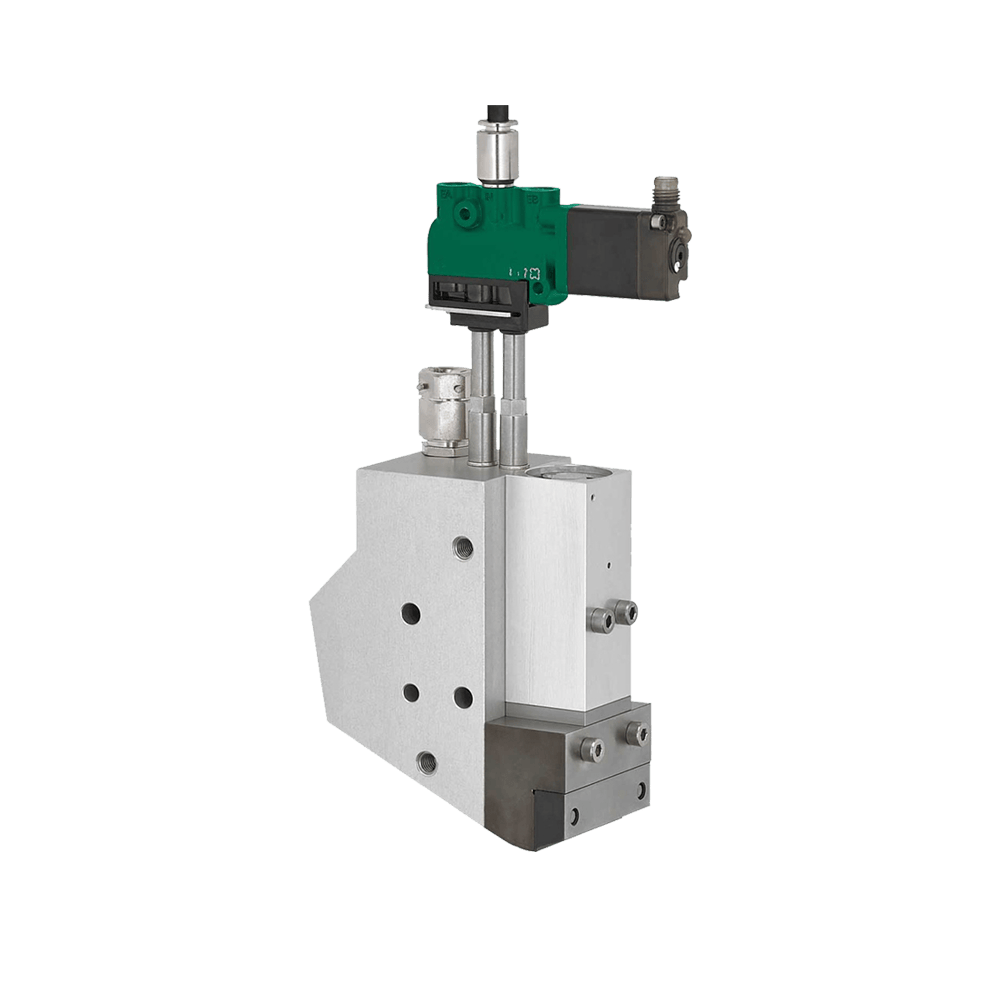

FK-IT Coating Head

FK-IT Coating Head

Designed for intermittent and continuous coating with flexibility to adjust coating width

The hot melt coating heads of the FK IT series are designed for intermittent and continuous coating of thermoplastic adhesives. Thanks to simple and cost-effective mask technology, they can be flexibly adjusted for the respective application. The FK IT coating heads are characterized by a precise adhesive tear-off behaviour and coating weight, also with high production speeds and fast switching times. The coating heads are mainly used in processes of the graphical and packaging material industry, as well as in other areas.

The application heads are used for surface coating on continuous material sheets as well as for surface coating on sheet feed in folding machines. The coating heads are double-acting with the jetting element closing negatively. This functionality ensures precise adhesive application and tear-off from start to finish. The application pattern can be flexibly adjusted using different mask shapes and thicknesses.

Share

Skip to content

Skip to content