| TECHNICAL DATA | |

|---|---|

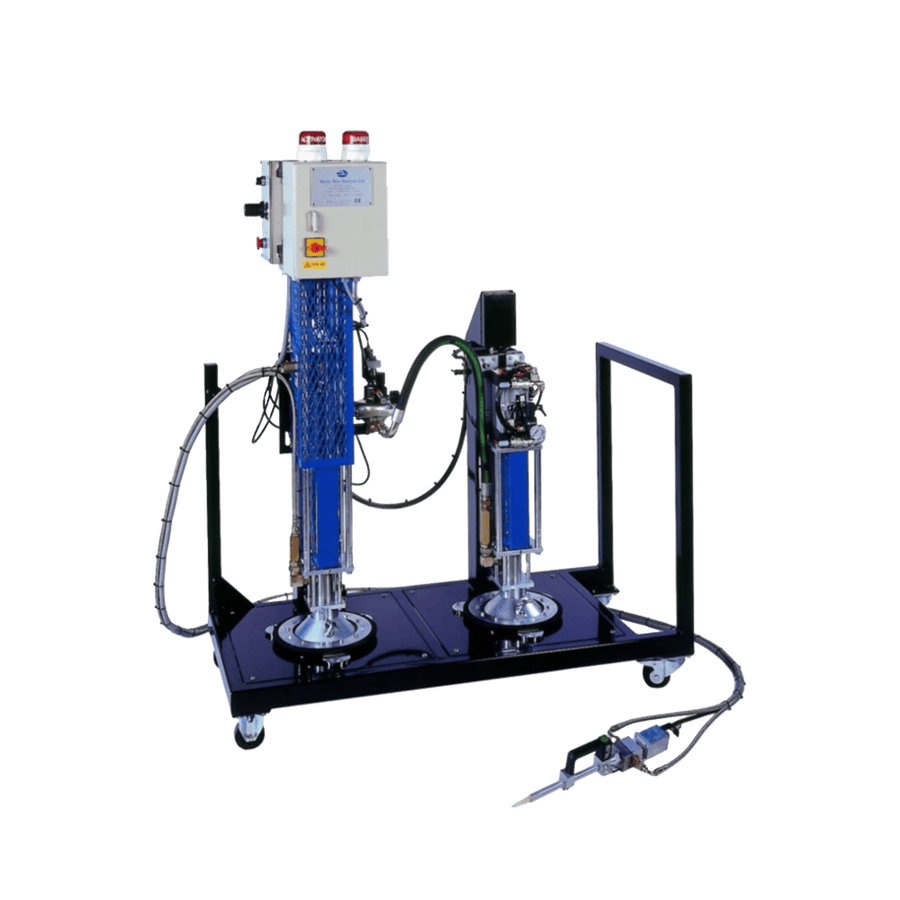

| PAR 3C & PAR 3CT | |

| Ratio Range Capability | 1:1 to 14:1 (depending upon pumps selected) |

| Viscosity acceptance | Up to 500,000 mPa.s (depending upon material thixotropy) |

| Shot size | Available from approx. 1.2ml up to 63ml at a ratio of 1:1 by volume |

| Cycle Rate | Up to 30 shots per minute (depending upon viscosity) |

| Mixing | Disposable Static |

| Reservoir Capacity | PAR 3C: 6lt. (1,58 gal) stainless steel with silica gel moisture protection PAR 3CT: 18 It (4,74 gal) |

| TECHNICAL DATA | |

|---|---|

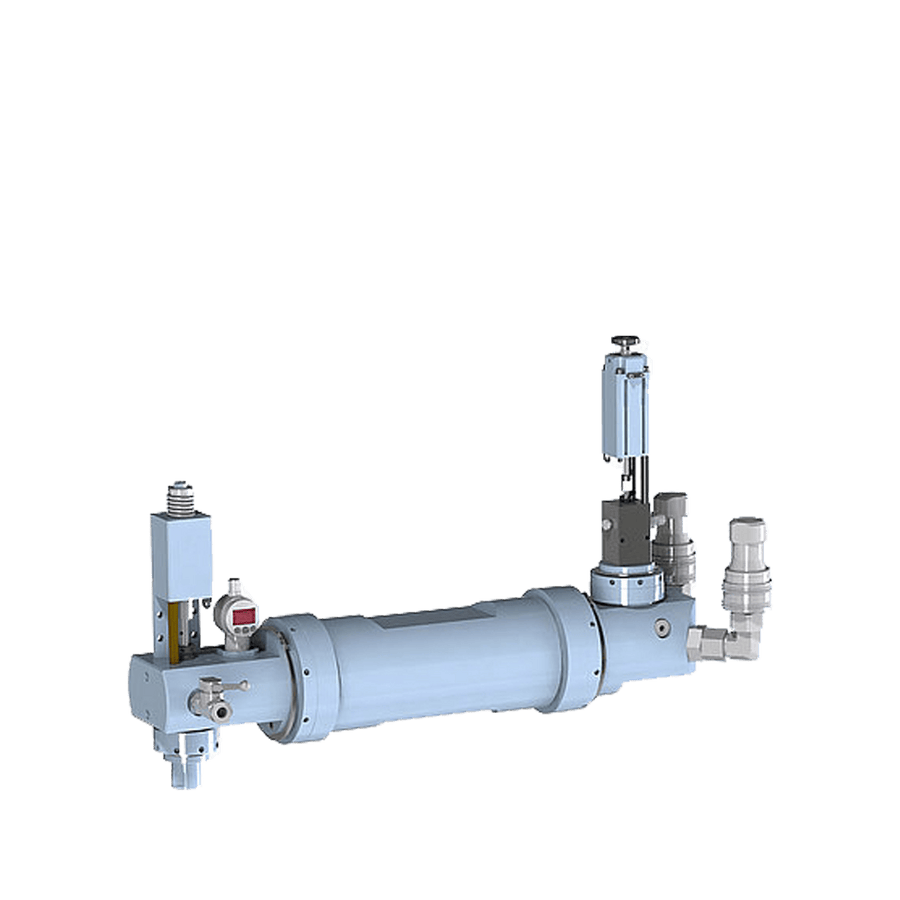

| PAR 3CM | |

| Metering Pumps | Single acting positive displacement |

| Mixer Valve | Pneumatically operated TSV602 Mixer Valve |

| Ratio Range Capability | 1:1 to 14:1 (depending upon pumps selected) |

| Viscosity acceptance | Up to 500,000 mPa.s (depending upon material thixotropy) |

| Shot size | Available from approx. 1.2 ml up to 63 mI at a ratio of 1:1 by volume |

| Cycle Rate | Up to 30 shots per minute (depending upon viscosity) |

| Mixing | Disposable Static |

| Reservoir Capacity | 6 It stainless steel with silica gel moisture protection |