| Technical Data | |||

|---|---|---|---|

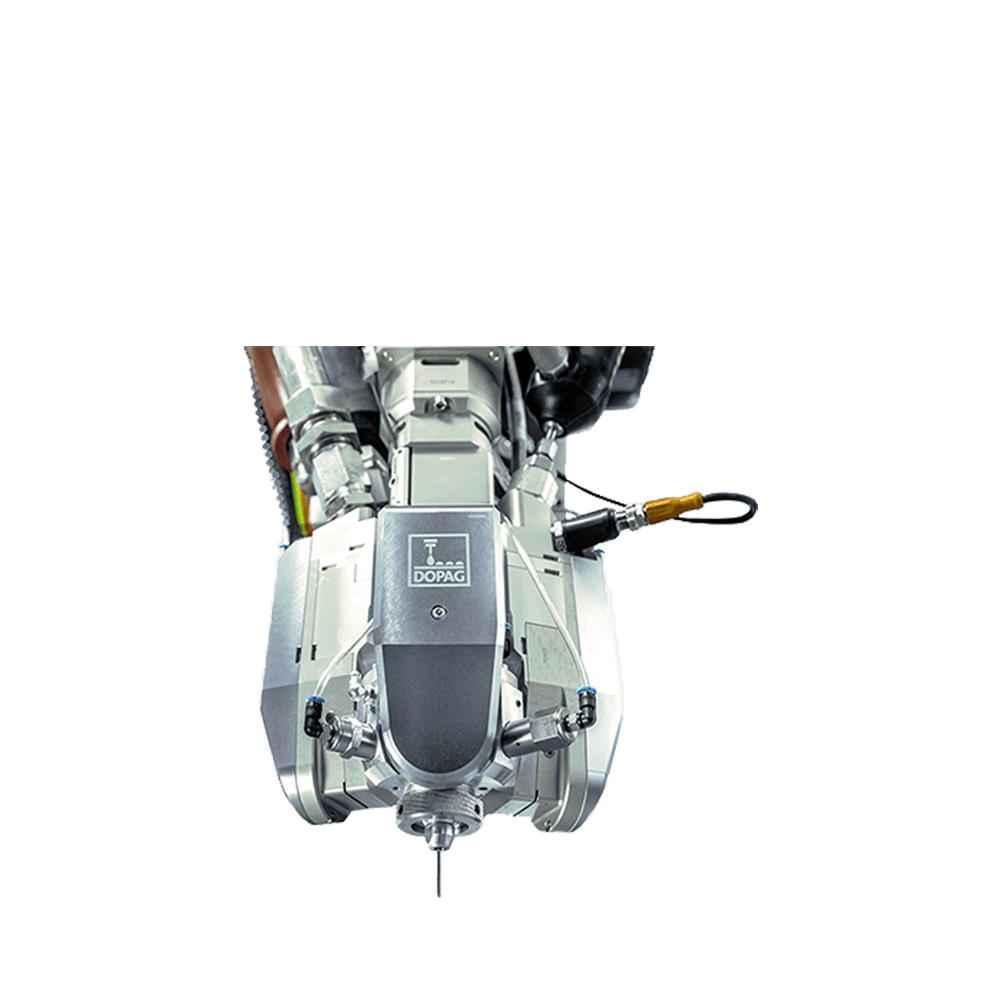

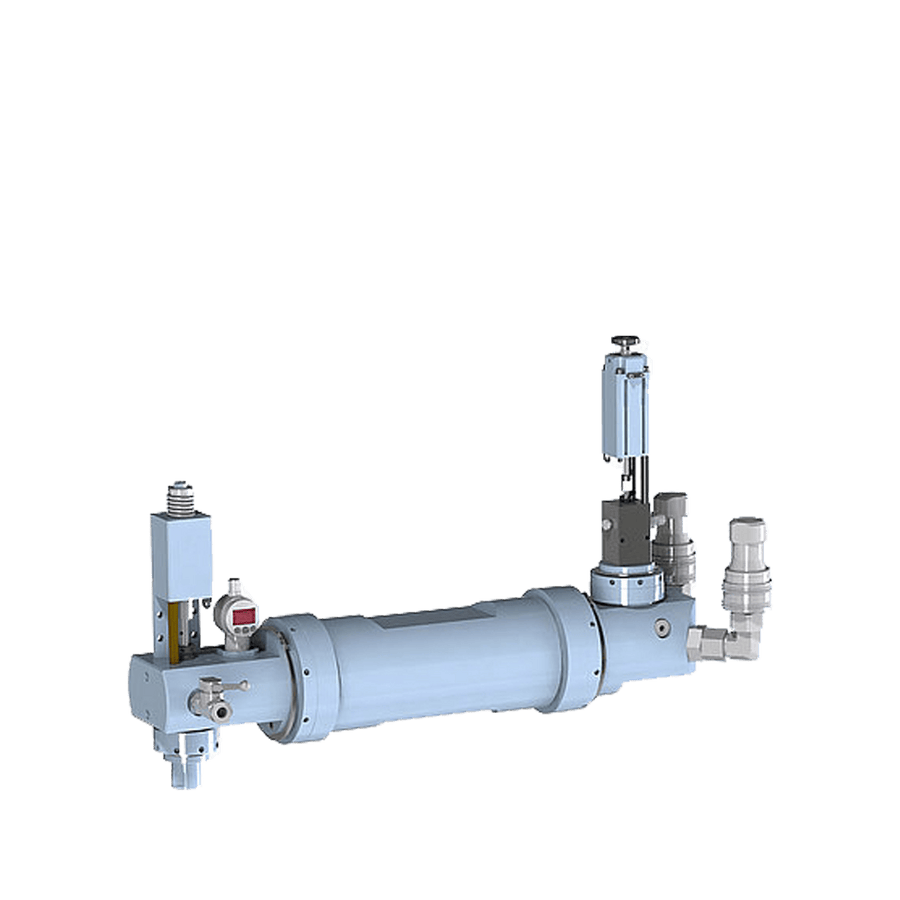

| Mixing head P1 | Mixing head P2 | Mixing head P3 | |

| Available in three mixing chamber sizes [cm] | 0,2 0,4 0,8 | 1,0 1,6 2,0 | 2,5 4,0 8,0 |

| Discharge capacity [g/s] (Depending on the material, mixing ratio and viscosity) |

0,1 -1,6 | 0,5 -4,0 | 1,2 -30,0 |

| Metering accuracy (Depending on the material, mixing ratio and viscosity) |

.+/-1% | .+/-1% | .+/-1% |

| Control unit | Motion control and visualisation: Metering control: MR40 B&R |

Metering Motion control and visualisation: B&R control: MR40 |

Metering Motion control and visualisation: B&R control: MR40 |

| Operating unit | 10.1″ handheld operating box Optional 5.6″ operating panel |

10.1″ handheld operating box Optional 5.6″ operating panel |

10.1″ handheld operating box Optional 5.6″ operating panel |

| Mixing ratio | from 100:1 to 1:100 infinitely variable |

from 100:1 to 1:100 infinitely variable |

from 100:1 to 1:100 infinitely variable |

| Selectable mixer speed | 1-3,000 U/min infinitely variable |

1-3,000 U/min infinitely variable |

1-3,000 U/min infinitely variable |

| Weight | approx. 12 kg (incl.drive and attachment parts) |

approx. 12 kg (incl.drive and attachment parts) |

approx. 12 kg (incl.drive and attachment parts) |

Experience in the industrial field of more than 40 years, we do not want to be just your supplier, but rather, we want to be your perfect partner to share the experience together

SOUTHERN SUPPLY CO., LTD.

- 442 Sukhonthasawat Rd., LatPhrao Bangkok 10230

- E-Mail : sales@soutthern-supply.net

- Tel : 02-5788490 - 4

- Fax : 02-5531233