| Technical Data | |

|---|---|

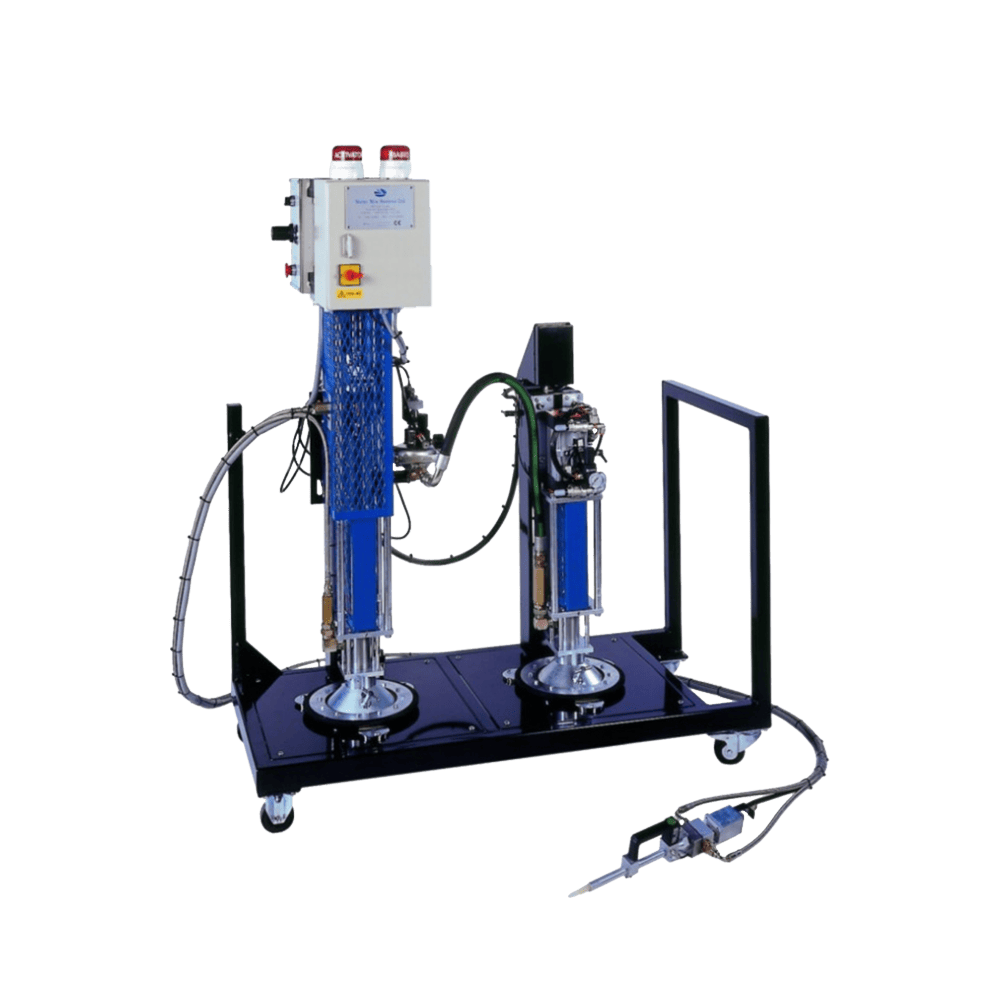

| PAR 20 & PAR 20C | |

| Ratio Range Capability | 1:1 to 12:1 (depending upon pumps selected) |

| Viscosity acceptance | Up to 1,500,000 mPa.s |

| Shot size | Available from approx. 11ml up to 108ml at 10:1 volumetric ratio |

| Cycle Rate | Up to 15 shots per minute (depending upon viscosity) |

| Mixing | Disposable Static |

| Major component drum/pail size | Typically approx. 20lt (5,27 gal)/25It (6,58 gal) (depending upon drum dimensions) |

| Minor component reservoir size | PAR 20: 18It (4,74 gal) stainless steel |

| Minor component drum/pail size | PAR 20C: approx. 20lt (5,27 gal) |

Experience in the industrial field of more than 40 years, we do not want to be just your supplier, but rather, we want to be your perfect partner to share the experience together

SOUTHERN SUPPLY CO., LTD.

- 442 Sukhonthasawat Rd., LatPhrao Bangkok 10230

- E-Mail : sales@soutthern-supply.net

- Tel : 02-5788490 - 4

- Fax : 02-5531233