PRODUCT

Spiral Mixer

Spiral Mixer

Using simple, time-proven geometry, Nordson EFD’s patented disposable Spiral Mixers™ deliver complete and thorough mixing for a wide variety of two-component materials.

Ideal for single-use fluid dispensing applications, the elements in these mixers are 180° helical twists alternating in either right- or left-hand rotation. These alternating elements are joined so that their leading and trailing edges are mutually perpendicular.

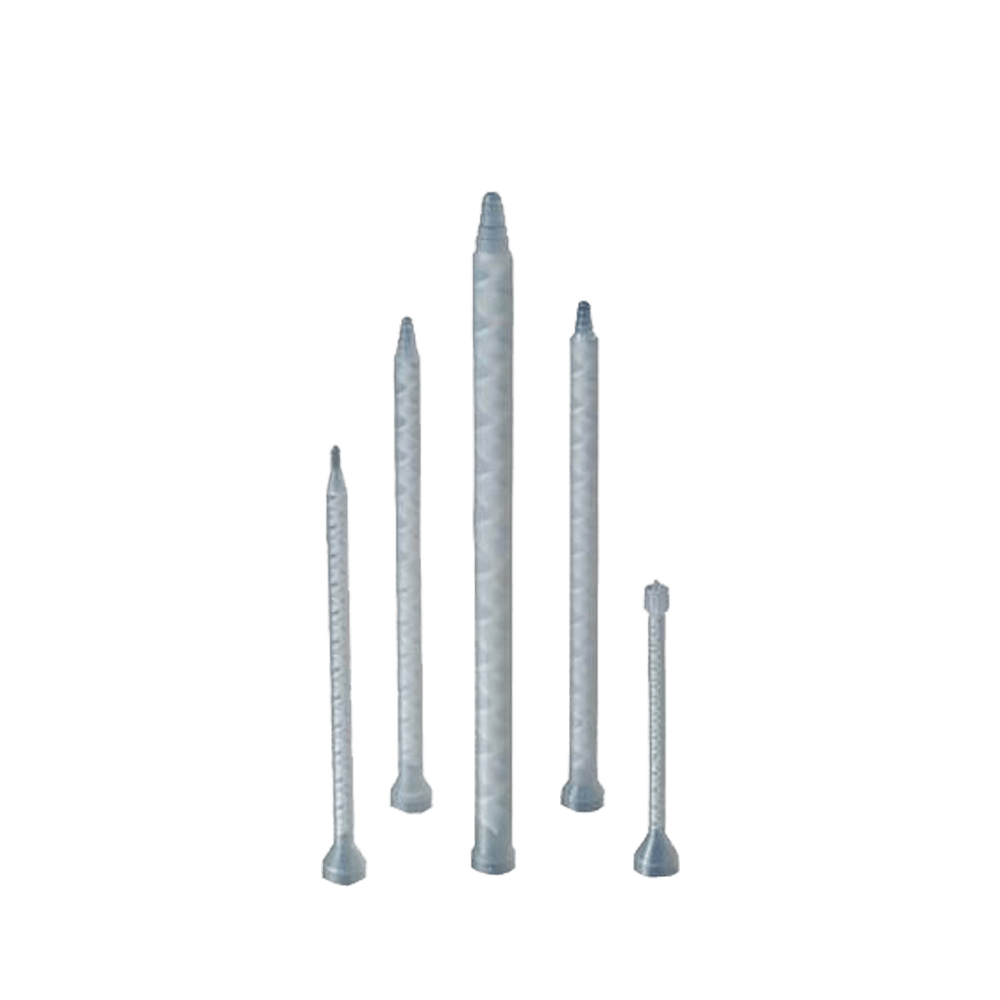

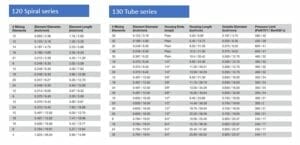

Series 120 Disposable Mixing Elements

Our plastic spiral mixing elements, with patented “Apple Core” cross section, are injection-molded in one operation to ensure excellent quality control and low unit cost. The “Apple Core” geometry ensures long life and a great flow rate. It also flushes clean with less solvent. We recommend Series 120 elements made of acetal for most applications.

Series 140 Disposable Plastic Tube Mixers

Ideal for messy or short pot life adhesives, Series 140 mixers’ low-cost, all-plastic assembly allows disposal of the mixer instead of solvent purging or baking. Its translucent housing allows its interior to be inspected to determine its condition. Its acetal interior gives it the toughness and chemical resistance to be inert to common solvents. Maximum service temperature is 250° F (121° C).

Series 141 Disposable Plastic Frother Mixers

The unique extended design of our Series 141 mixers improve reach and reduce spiraling of urethane foam after the mix to allow more accurate dispensing. This mixer prevents foam from exiting in two streams by extending the tube length beyond the elements. The empty extension eliminates material separation.

Series 160 Disposable Plastic Spiral Bell Mixer

The nozzle on the Series 160 Spiral Bell Mixer is designed with a “bell” icnlet. The inlet fits Nordson EFD valve manifolds and large volume cartridges that separately port the A and B materials directly into the mixer. Cleanup of the plastic spiral bell mixer involves simply removing the bell mixer and wiping the manifold face clean. In the case of the cartridges, because of the divider fin, simply remove the mixer. A metal jacket is recommended if the working pressure inside the nozzle exceeds 150 psi (10 bar) (only used with meter mix valves or manifolds).

Series 160AA Disposable Mixers for Quick Spray System

Our Series 160AA low-pressure, air-assisted spray systems for two-component coatings produce consistent round spray patterns on irregular surfaces. Designed for use with conventional meter/mix equipment or our two-component cartridge systems, these mixers include a round air cap, which produces a full-cone pattern completely filled with spray drops. The reactive coating is mixed within the disposable static mixer. At the mixer outlet, air is introduced which atomizes the liquid stream. The degree of atomization can be adjusted by regulating the airflow rate. Since the reactive coating is contained completely within the mixer, cleanup is minimal.

Series 162A Disposable Plastic Spiral Bell High Flow Mixer

Ideal for high flow rate meter mix applications, Series 162A are Nordson EFD’s largest disposable bell mixers with elements 19.9 mm (0.784”) in diameter. Rugged nylon housing includes an oversized bell inlet. Attach extensions or other types of accessories to the downstream outlet designed with a 12.7 mm (0.5”) NPS male thread.

Series 190 Disposable Plastic Spiral Bayonet Mixers

Ideal for mixing epoxies, urethanes, acrylics, and silicones, our Series 190 mixers are designed for use with most 50mL two-component cartridges. Featuring a standard Bayonet connection, it is available in five diameter sizes with four housing outlet styles, including: Slip Luer, Full Bore, H-Tapered, and Stepped. Slip Luer outlets are the standard offering. Full Bore outlets ensure maximum flow with minimal back pressure. H-Tapered outlets provide precise adhesive placement.

Series 260 Disposable Plastic Spiral Bell Mixers

Our Series 260 mixers are available in Standard Bell and Integral Nut inlet connections. Integral Nut eliminates the need for a separate retaining nut. These mixers come in diameters ranging from 8.5 mm (0.355”) to 20.0 mm (0.789”). Outlet types include: Stepped, Barb Ext, Tapered, and Full Bore.

Share

Skip to content

Skip to content