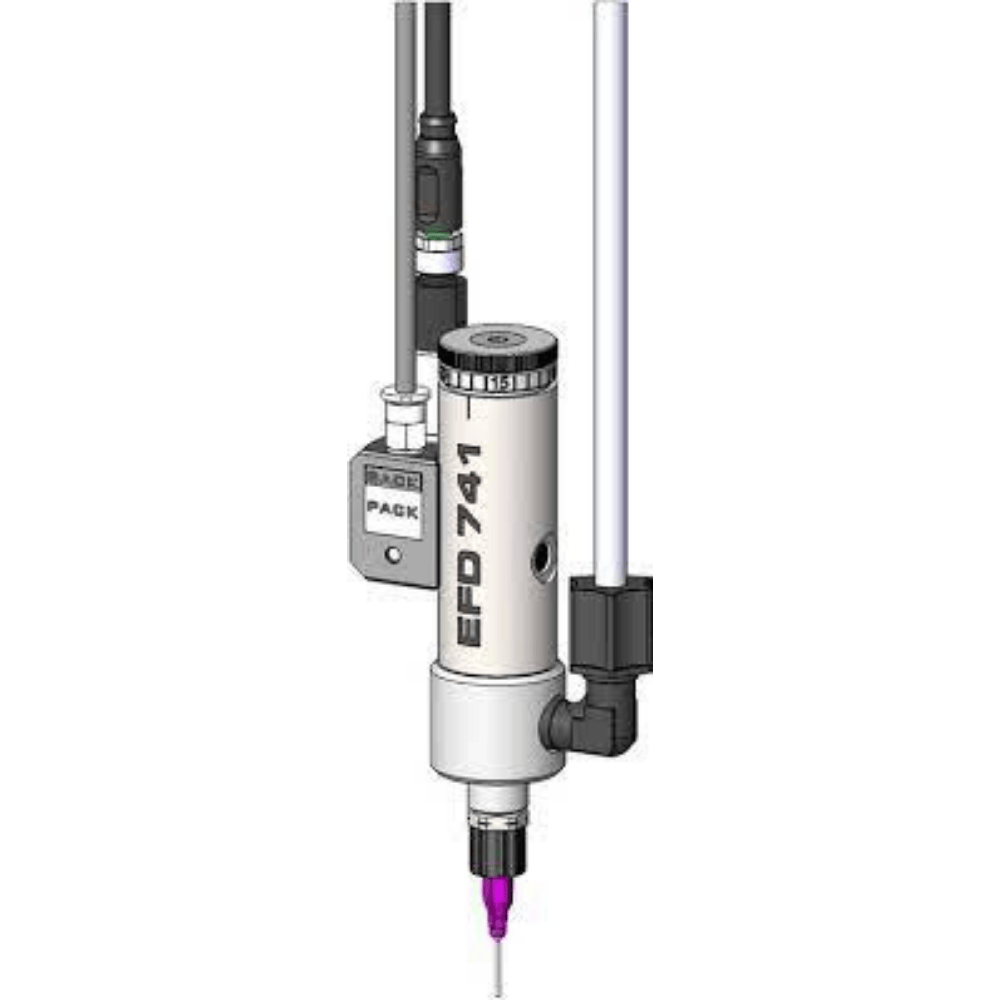

The 741V Series needle valve design applies low viscosity assembly fluids with accurate, extremely close repeat deposit control.

During operation, controlled pulsed air acts on the piston to withdraw the needle a preset distance from the needle seat to provide exact, repeatable fluid flow. The stainless steel needle seats in the tip adapter, virtually eliminating dead fluid volume between shots.

The Nordson EFD needle valve features adjustable fluid flow control.

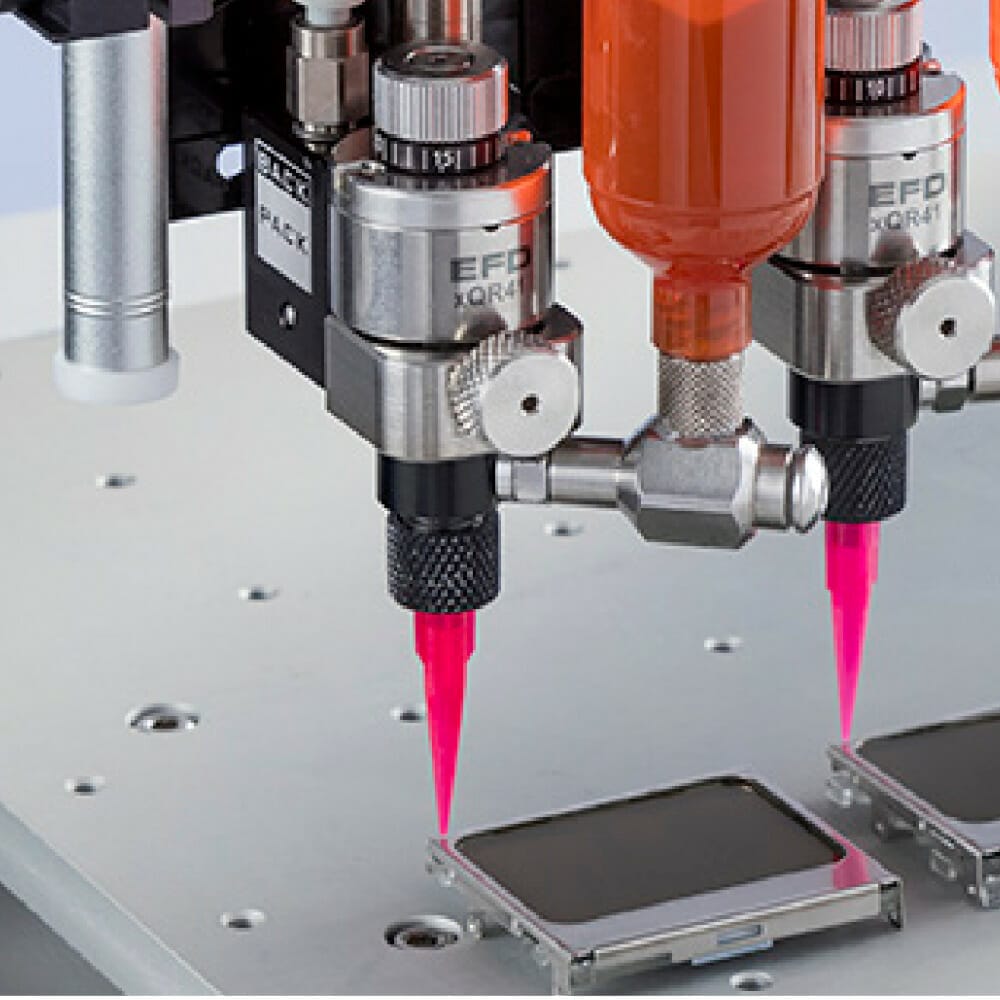

With the new QR technology, the xQR41V Series needle valve features a (QR) Quick Release clasp, modular design, and 60% smaller form factor, with being designed for precise, consistent fluid control, The QR clasp makes it easy to remove the fluid body from the valve in seconds – no tools required. Because the valve can stay mounted while the fluid body is cleaned, changing out fluid takes less than 2 minutes, which significantly reduces downtime while increasing productivity.

A 60% smaller form factor allows the xQR41V to dispense in tighter spaces and at more complex angles. The ability to mount more valves per fixture plate increases production capacity.

Skip to content

Skip to content