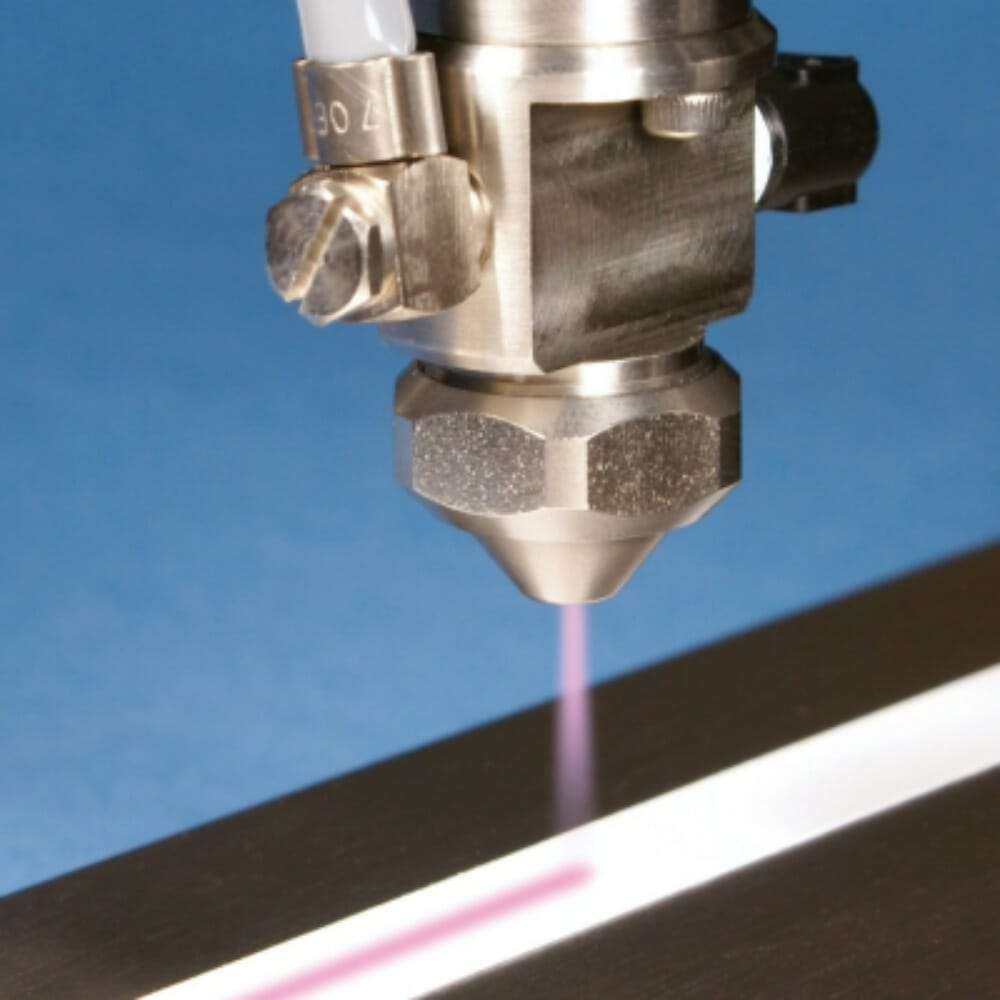

The 787MS-SS MicroSpray™ valve’s innovative design incorporates a small gauge disposable dispensing tip to apply a precise, uniform spray pattern more than 30% smaller than standard spray valves. Using Low Volume Low Pressure (LVLP) technology it produces spray patterns as small as 3.3 mm (0.13”) and as great as 19 mm (0.75”) in diameter. A small gauge, 0.3 mm (0.013”) to 0.1 mm (0.004”), dispense tip replaces the standard spray nozzle, concentrating the LVLP air used to atomize coatings into smaller spray patterns.

The 787MS-SS increases throughput and allows greater process control, while reducing production costs and rejects. The valve needle seats in the hub of the dispensing tip, virtually eliminating dead fluid volume between shots.

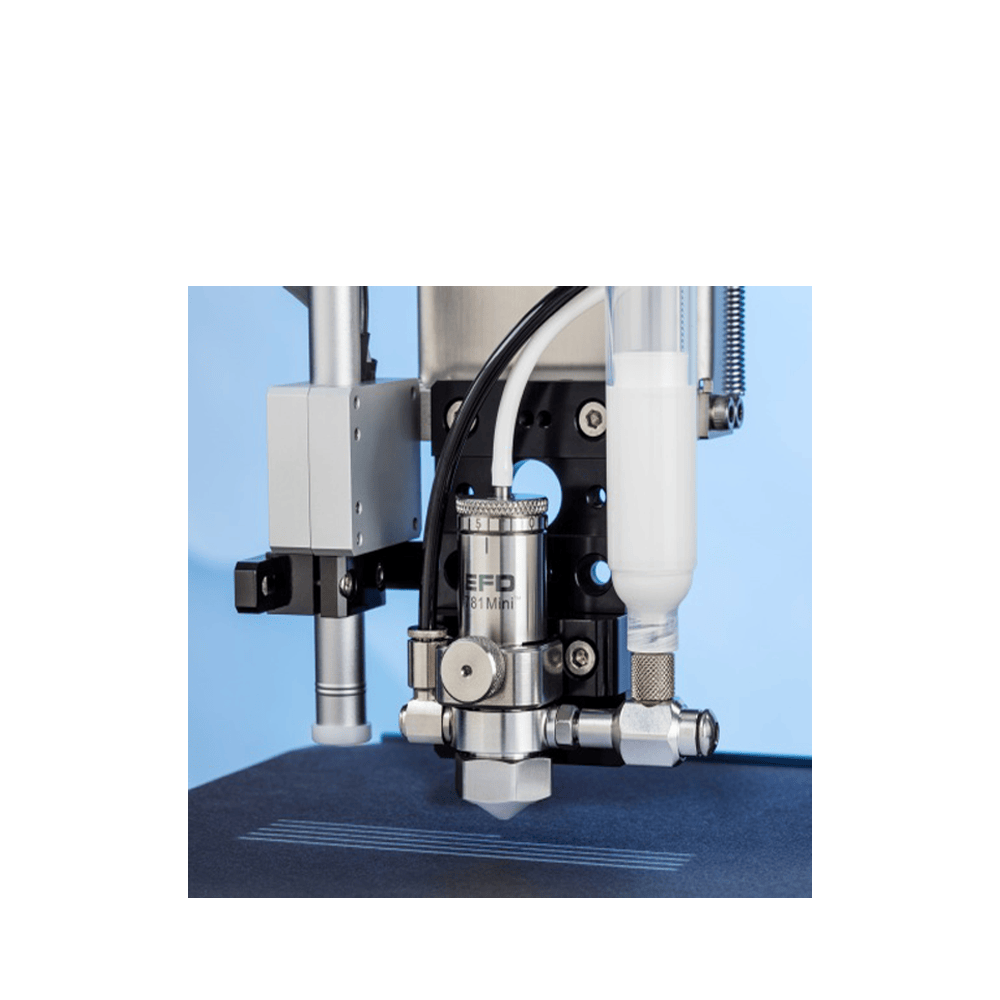

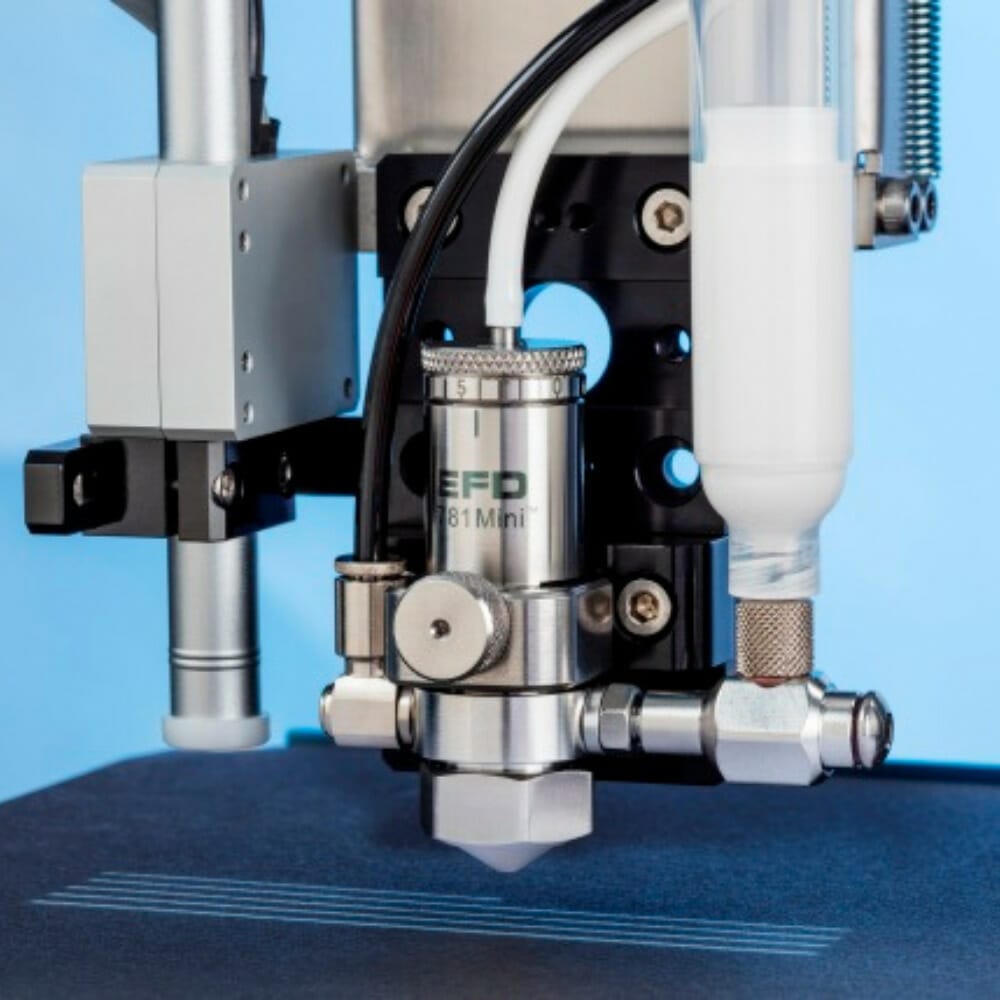

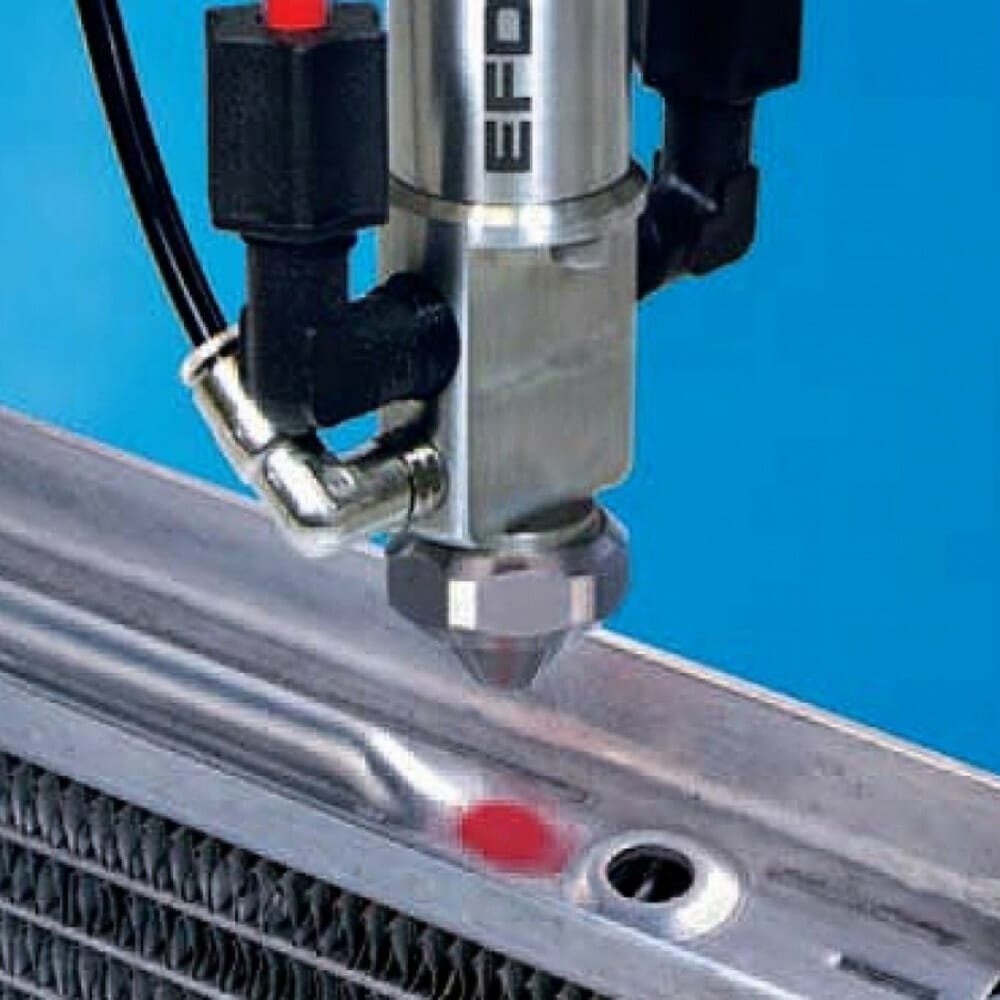

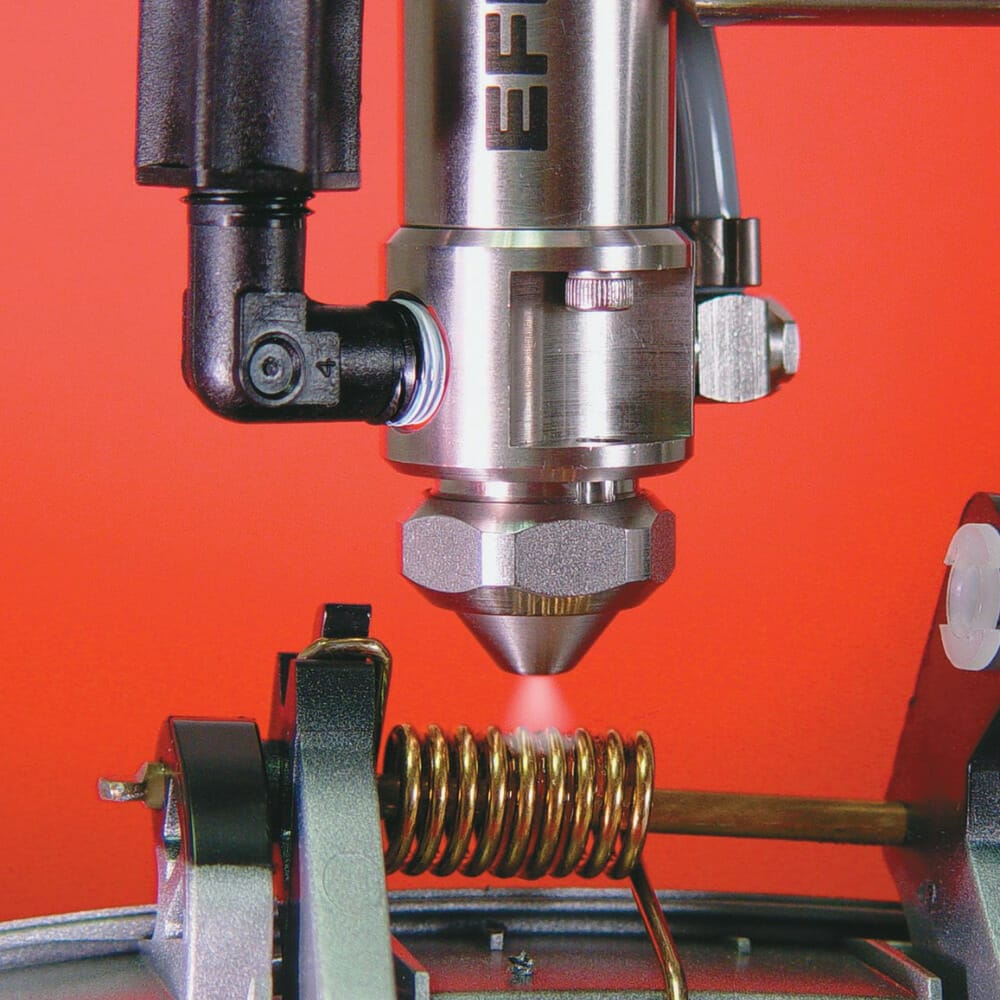

Another valve series is the 781Mini™ spray valve. It’s innovative design directs nozzle air pressure more consistently for exceptionally more uniform, narrower spray patterns than previously possible. Using Low Volume Low Pressure (LVLP) technology, the 781Mini provides precision spray control with consistent spray patterns as narrow as 1 mm (0.04”) wide.

With a 60% smaller form factor than conventional spray valves it’s possible to mount more valves per fixture plate for high volume applications. It’s also possible to install in tighter manufacturing environments or complex spaces.

The 781Mini’s enhanced spray nozzle design improves spray pattern uniformity, providing better accuracy and edge definition. Its unique, patented (QR) quick release clasp reduces downtime to seconds when servicing the valve

Skip to content

Skip to content