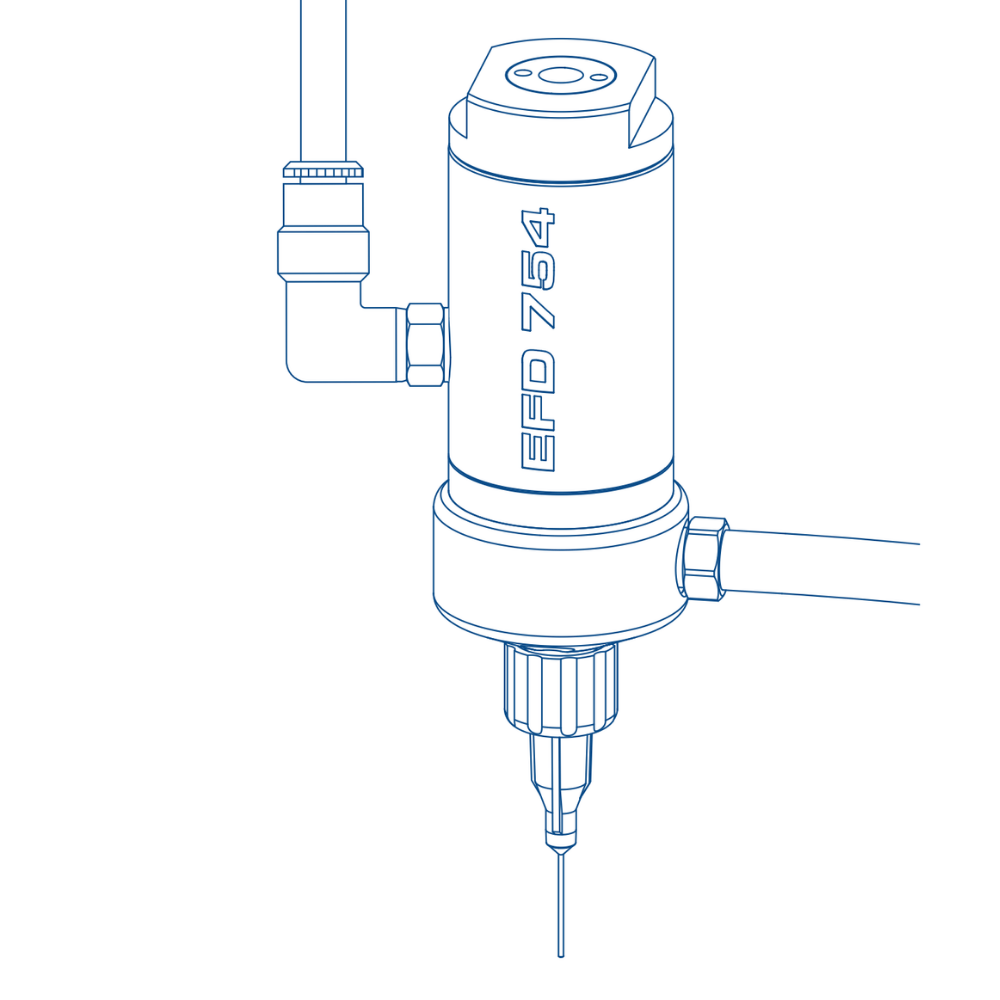

Nordson EFD’s 754V aseptic dispense valve features a smooth fluid flow path that is free of any entrapment areas. FDA-compliant wetted parts make the valve suitable for CIP (Clean-In-Place) and SIP (Sterilize-In-Place) medical assembly processes.

With a flow path free of entrapment areas, the 754V provides fast, reliable operation. This fosters faster cycle and batch speeds, while electro-polished valve fluid bodies increase durability and corrosion resistance.

Flow volumes range from 0.5 microliter deposits to a continuous flow rate of 14.0 milliliters per second. The valve closes clean at the end of each cycle, with a fast cutoff that eliminates drips. Internal threads have been removed to facilitate easy cleaning.

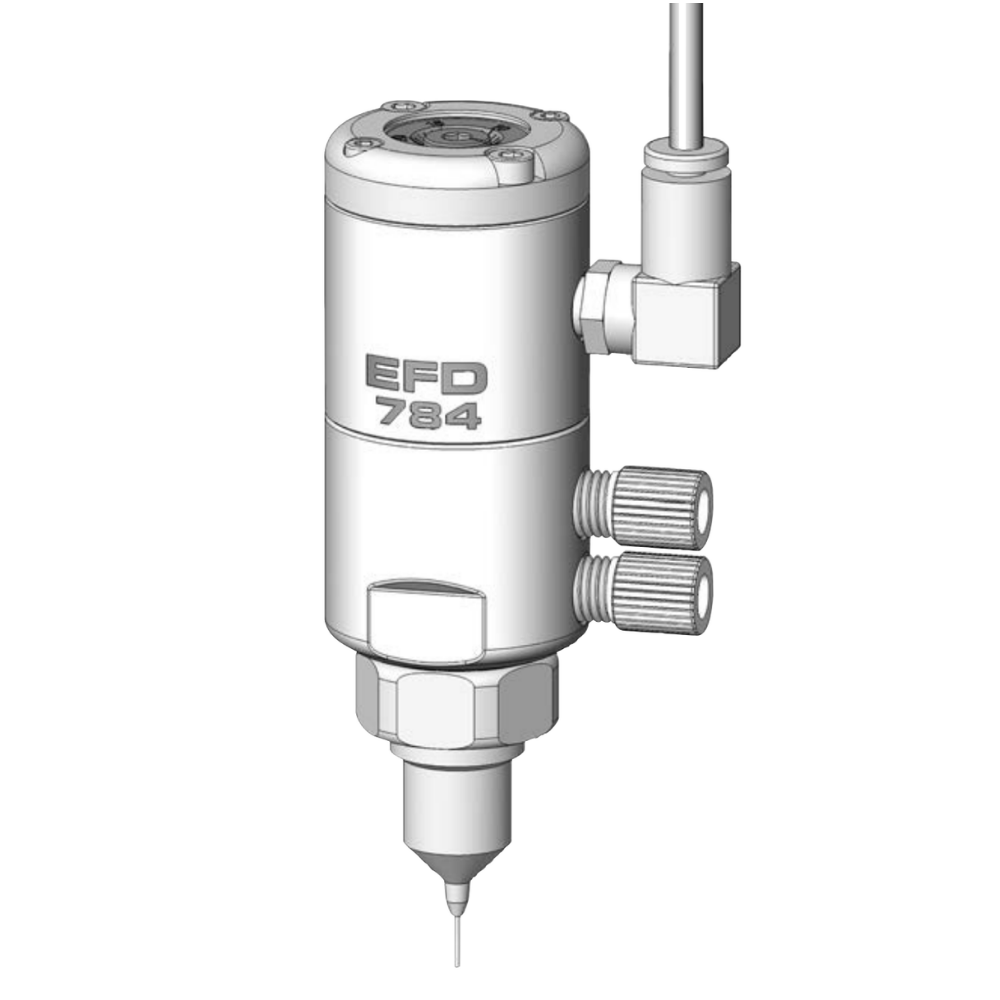

Another Valve series is the 784S-SS aseptic microspray valve, with FDA-compliant wetted parts, features a fluid flow path free of entrapment areas, ideal for sterile applications. Using Low Volume Low Pressure (LVLP) technology, the 784S-SS valve produces uniform spray patterns between 3.3 mm (0.13”) and 19.1 mm (0.75”) in diameter. It accurately controls the application of most low- to medium-viscosity fluids. For wider coverage, the 784S-SS-F model includes a fan air cap.

Its innovative design replaces a standard spray nozzle with a small gauge disposable dispensing tip, which concentrates the LVLP air used to atomize coatings into smaller spray patterns.

Our Aseptic valve wetted parts are made of 316L stainless steel and PTFE, making them suitable for CIP (Clean-In-Place) and SIP (Sterilize-In-Place) processes. This compact diaphragm valve is ideal for aseptic and sterile fluid applications.

Skip to content

Skip to content