PRODUCT

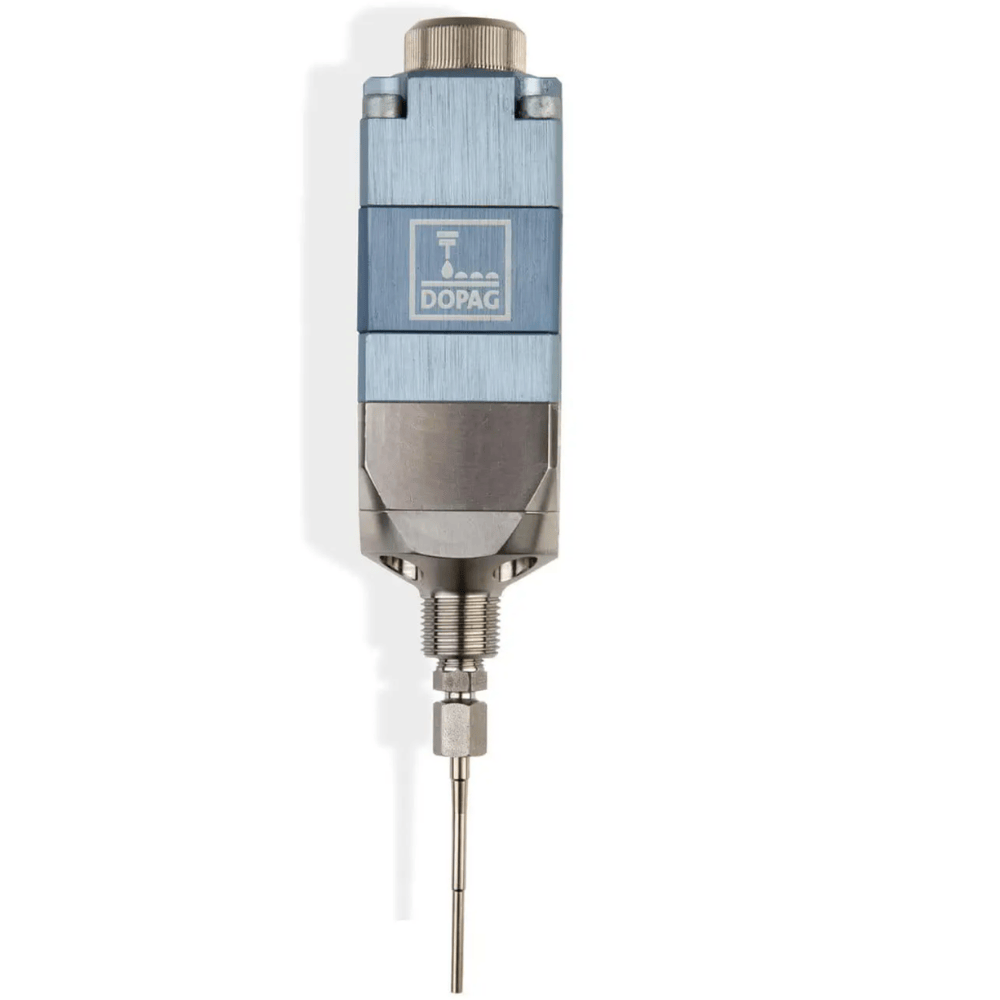

Membrane Dispensing Valve

Membrane Dispensing Valve

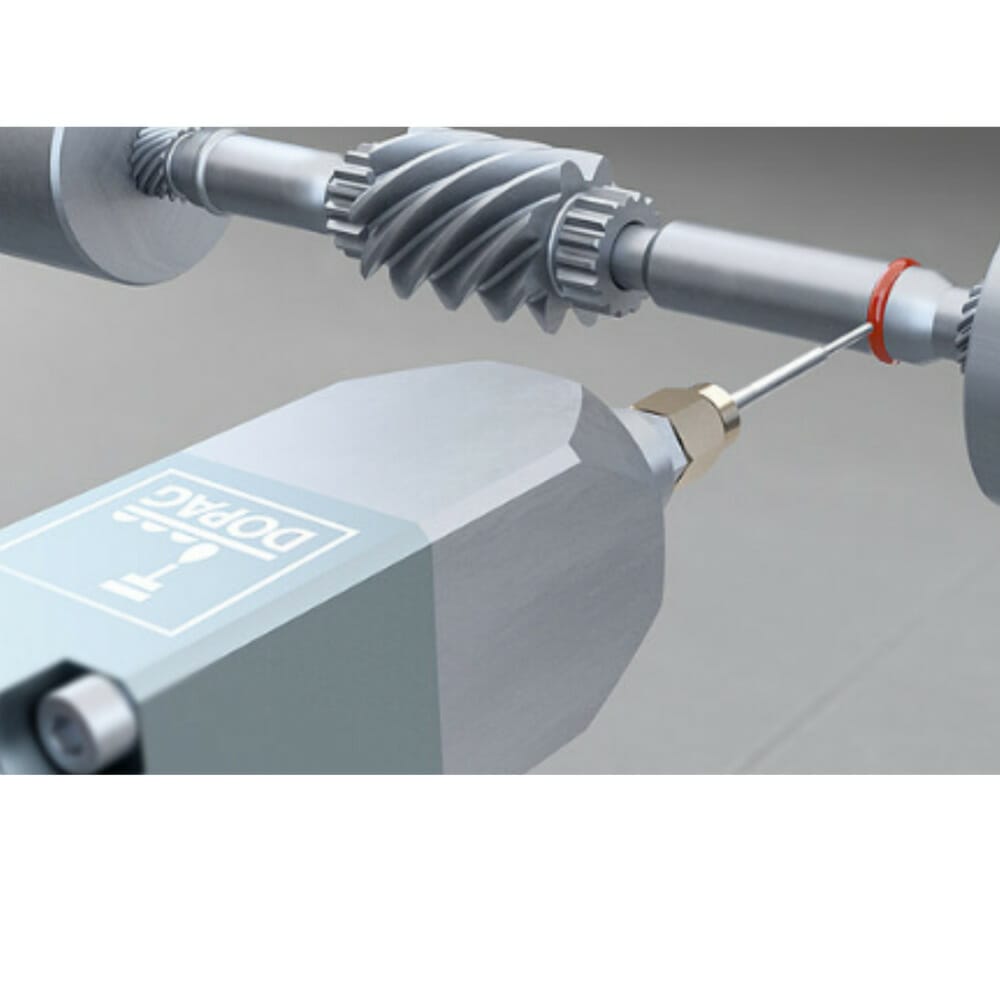

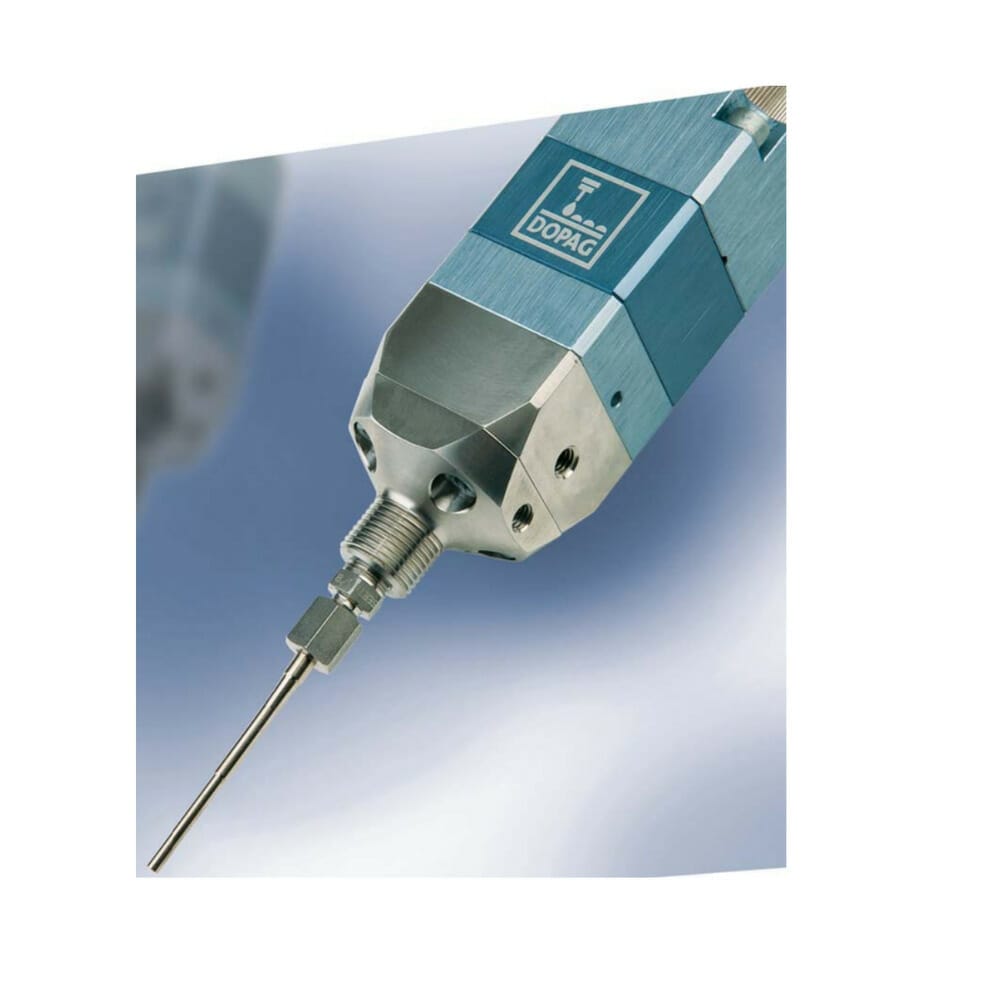

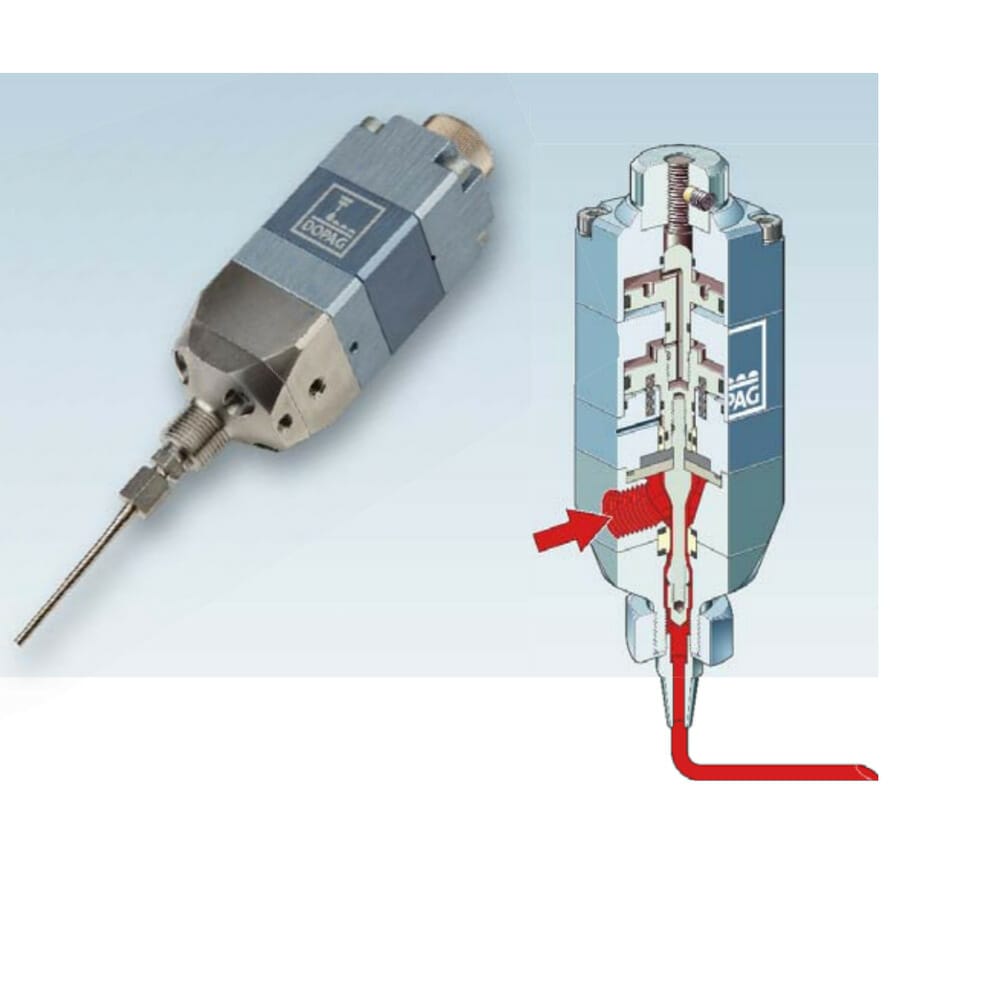

The advantage of membrane dispensing valves is their ability to process material with challenging properties in continuous shot applications. The valves are designed for care-free dispensing of low to high viscosity, filled or unfilled, abrasive or chemically reactive 1K fluids. Part of their structure is an integrated membrane that separates the pneumatic and the metering parts of the valve. As a result, only the valve head and the membrane come in contact with the material, while the material passageway can be easily flushed if necessary. The size of the orifice is regulated by stroke adjustment. Material dripping after shot completion is effectively prevented with the snuff-back mechanism. This valve is exceptionally easy on maintenance.

Features

– Continuous application (time-pressure dispensing)

– Internal diameter 2, 4 and 8 mm

– Max. input pressure 160 bar

– Snuff -back effect

Share

Skip to content

Skip to content