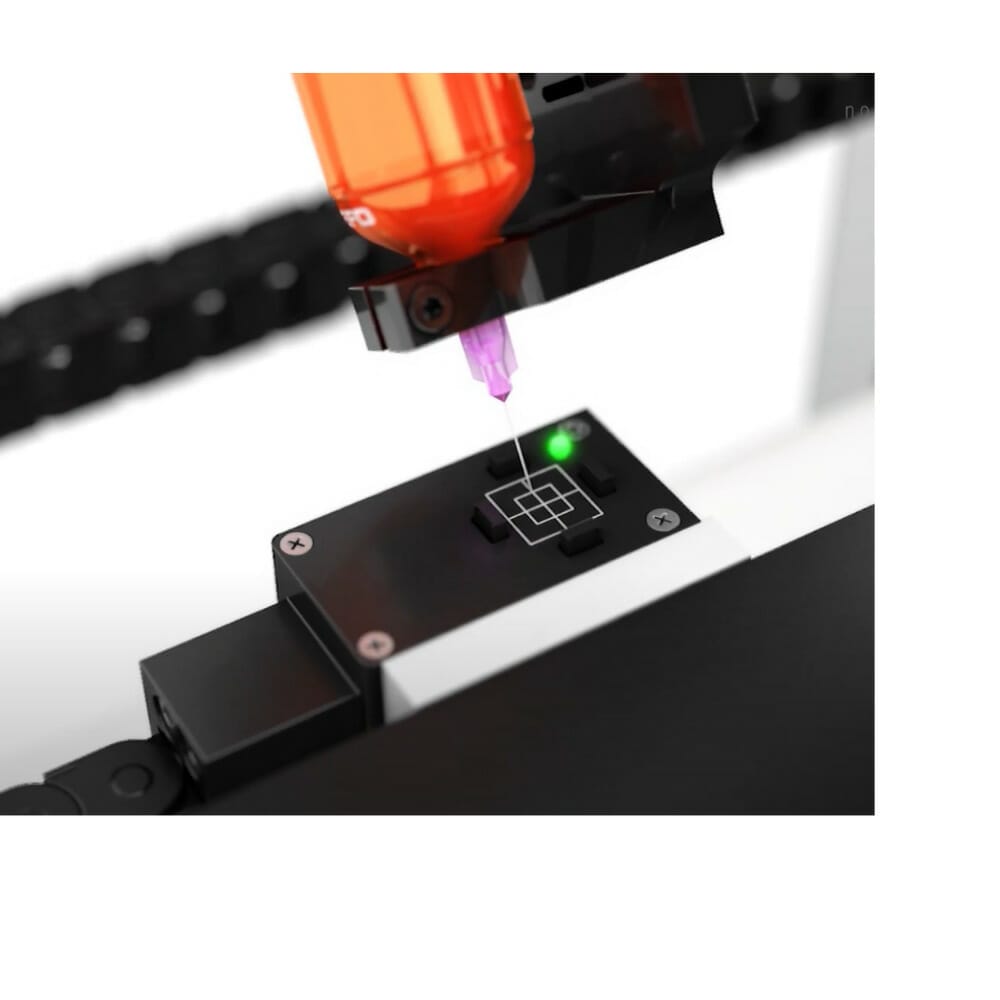

The R Series automated fluid dispensing system features specialized TeachMotion™ Teach Pendant software for market-leading repeatability and accuracy in fluid placement and positioning.

Its fourth axis allows for dispensing at any angle along the 360° rotation plane. With custom dispensing software, it’s easy to set up and program the system for dispensing applications in less time.

True 3D motion control simplifies programming of dots, lines, circles, arcs, compound arcs, and patterns on different planes. Simultaneous X and Y movement during R rotation makes it necessary to program only the R axis for true point programming.

The R Series features best-in-class repeatability at +/- 8 µm for higher throughput yields.

Features

– Simplified setup and programming via Teach Pendant

– Easy USB file upload and download

– Built-in tip recalibration sequence for easy dispense tip change alignment

– 360° rotation for ID and OD dispensing