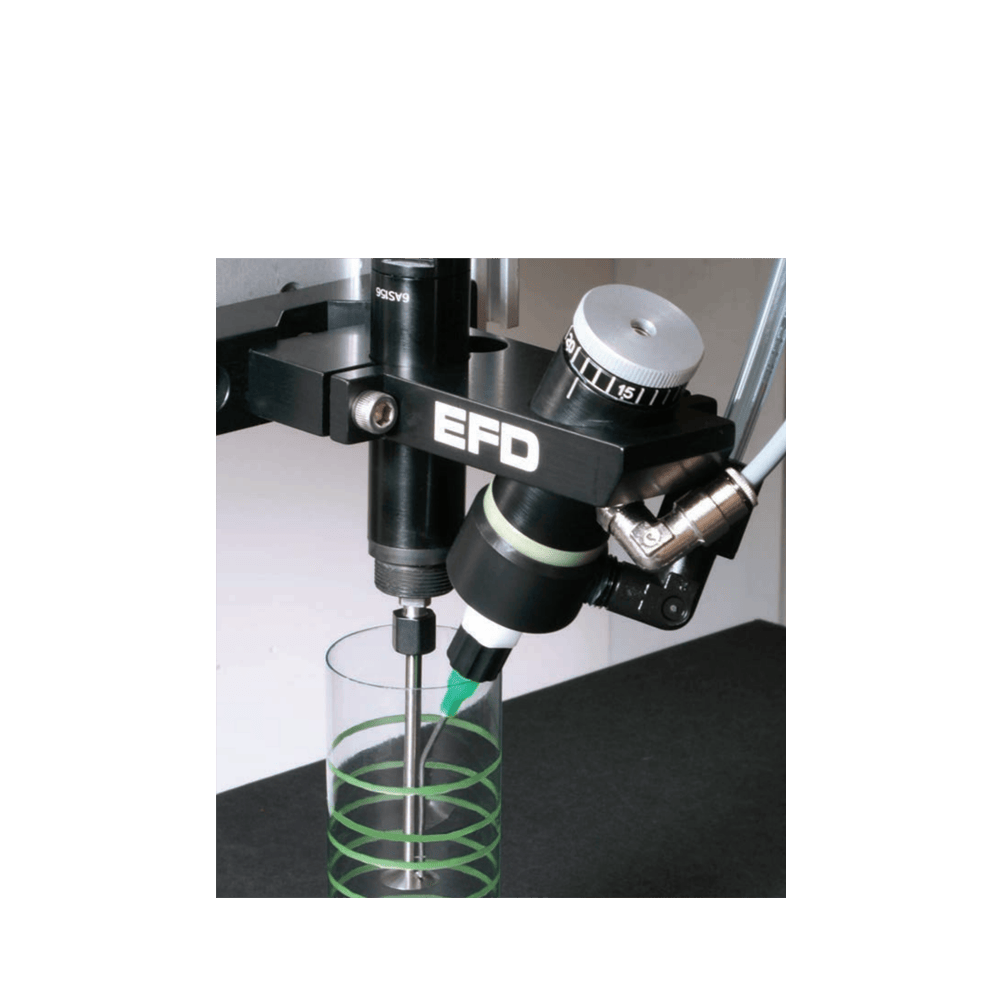

Nordson EFD radial spinner valve system provides an efficient, cost-effective way to apply production fluids inside cylindrical parts between 10.2 mm (0.4”) and 127 mm (5”) in diameter.

The system’s compact size and precision makes it ideal for processes where fluid must be applied inside small cylinders or confined to specific locations without overspray. Its inert wetted parts make it compatible with a wide range of reactive fluids such as cyanoacrylates and anaerobic adhesives. The valve dispenses a precisely metered amount of fluid onto a spinning disk attached to the motor. As fluid reaches the edge of the disk it spins off, forming a neat band inside the part.

The valve system’s low maintenance design also improves product performance and appearance while reducing downtime.

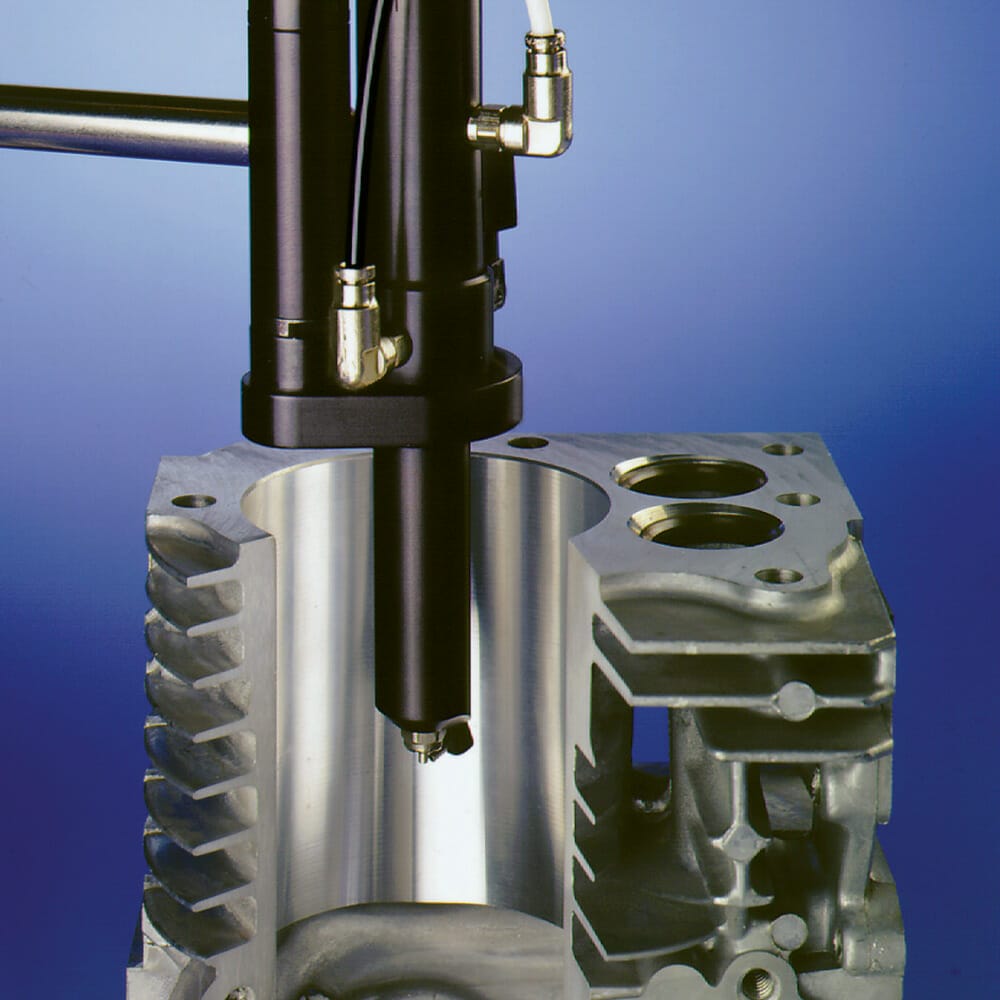

Another version is the 782RA Series radial spray valve. It’s unique design allows it to apply a precise, uniform 360° coating of lubricants, primers, and other low- to medium-viscosity fluids inside cylinders.

Using Low Volume Low Pressure (LVLP) technology, the air-actuated spray system atomizes the fluid while a precision air motor drives a rotating air cap, producing radial output to coat cylinders 25.4 mm (1.0”) to 304.8 mm (12.0”) in diameter.

Rotor length is 5.59 cm (2.2″) and reaches into cylinders with a minimum inner diameter of 2.54 cm (1.0″). High transfer efficiency with instant fluid cutoff at the end of the spray cycle ensures that coatings are applied evenly from startup to shutdown.

Skip to content

Skip to content