Continuous volumetric meter mix dispensing for two-component (2K) fluids provides industry-leading process control for manufacturers.

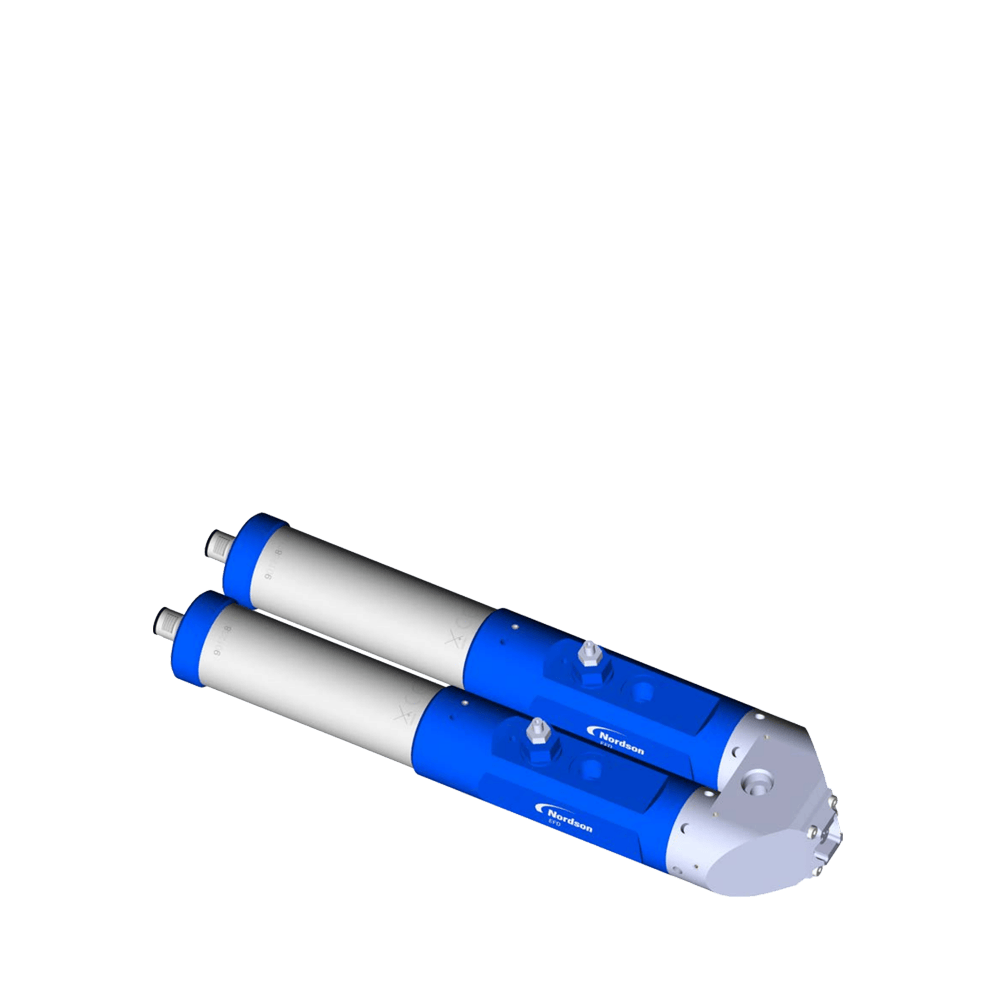

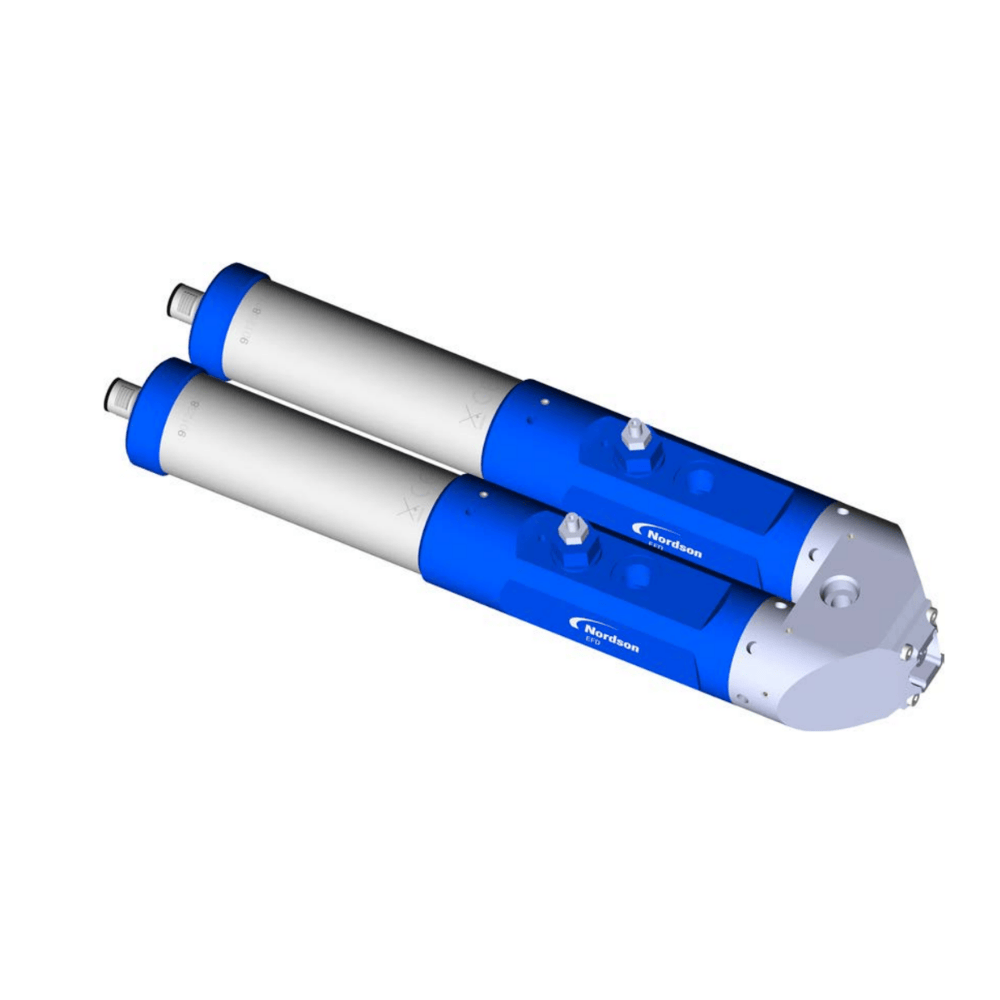

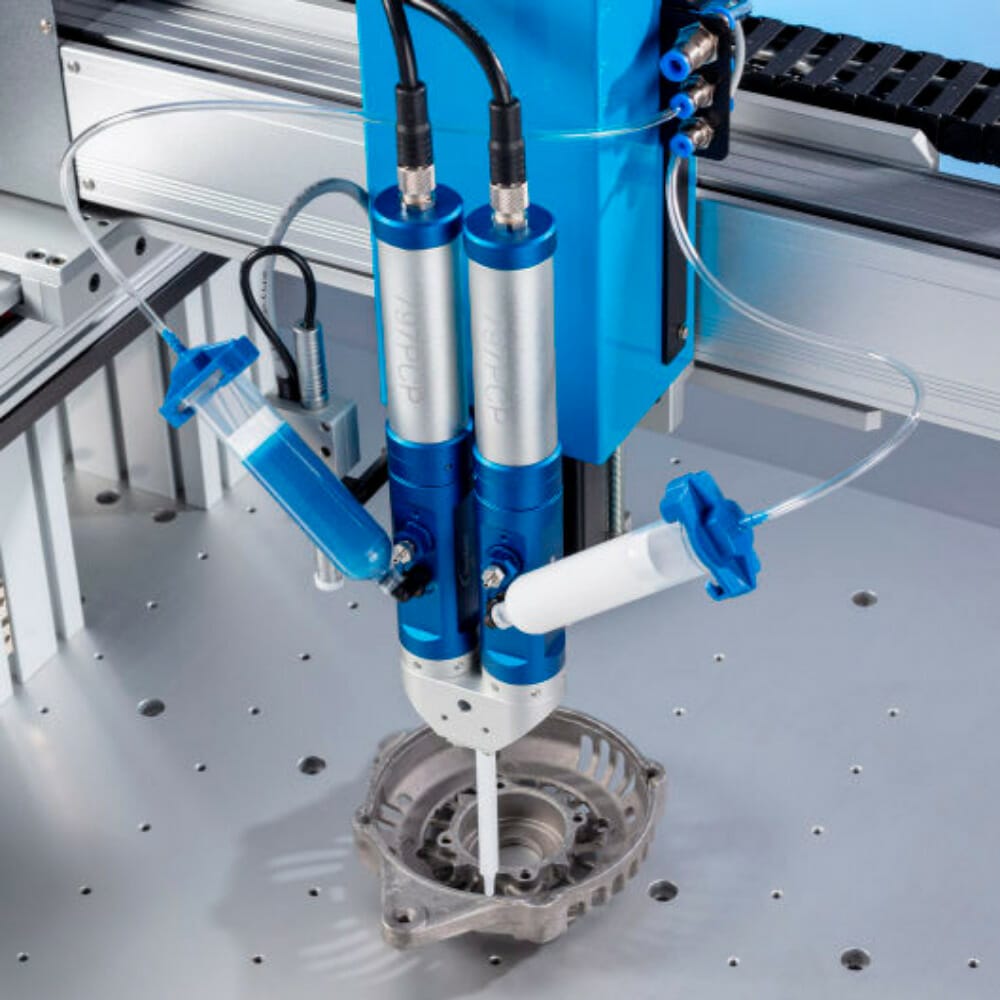

Nordson EFD’s 797PCP-2K Series pumps precisely meter accurate ratios of part A and part B materials through static mixers for highly repeatable dispensing with fluid deposit accuracy at +/- 1%. With a modular design that consists of two 797PCP-2K pumps and a manifold that accommodates a wide range of EFD’s disposable Series 190 spiral and Series 295 square Turbo mixers, Nordson EFD offers a total system solution backed by 50+ years of two-component fluid dispensing expertise.

This allows us to test your application in our global application labs and recommend the right two-component dispensing system, which can save time and costs when it comes to implementation.

797PCP-2K progressive cavity pumps come in three sizes – 0.01 mL, 0.05 mL, and 0.15 mL. This allows for multiple mix ratios for a wide range of applications.

Perfectly sealed metering chambers allow for continuous volumetric dispensing independent of fluid viscosity or changes in viscosity over time, making the pump system ideal for applying two-part epoxies. The continuous seal prevents shear, pulsation, and squeezing of fluid, which simplifies abrasive material dispensing.

Features and Benefits

Highly precise, continuous volumetric dispensing with 2K fluid volume accuracy at +/- 1% for exceptional process control

Modular design for multiple mix ratios and use in many different types of applications

Compatibility with a wide range of EFD static mixers simplifies implementation

Programmable suck-back provides more accurate dispensing without dripping or drooling

Compatible Fluids: Acrylics, Epoxies, RTVs and sealants, Silicones, Urethanes