| Technical Specification | |

|---|---|

| Flow rate | up to 4 //min, depending on mixing ratio and viscosit |

| Mixing ratio | 100:100 to 100:10, by volume |

| Maximum working pressure | 70 bar max. |

| Mixing system | static |

| Material characteristics | Material vessels 60 | |

| Power supply | 3 x400 V / 50 Hz |

| Max. air inlet pressure | 6 bar |

| Dimensions L x W x H | approx. 1,330 x 1,210 x 1,560 mm |

| Weight | approx.470 kg |

PRODUCT

LadoMix

LadoMix

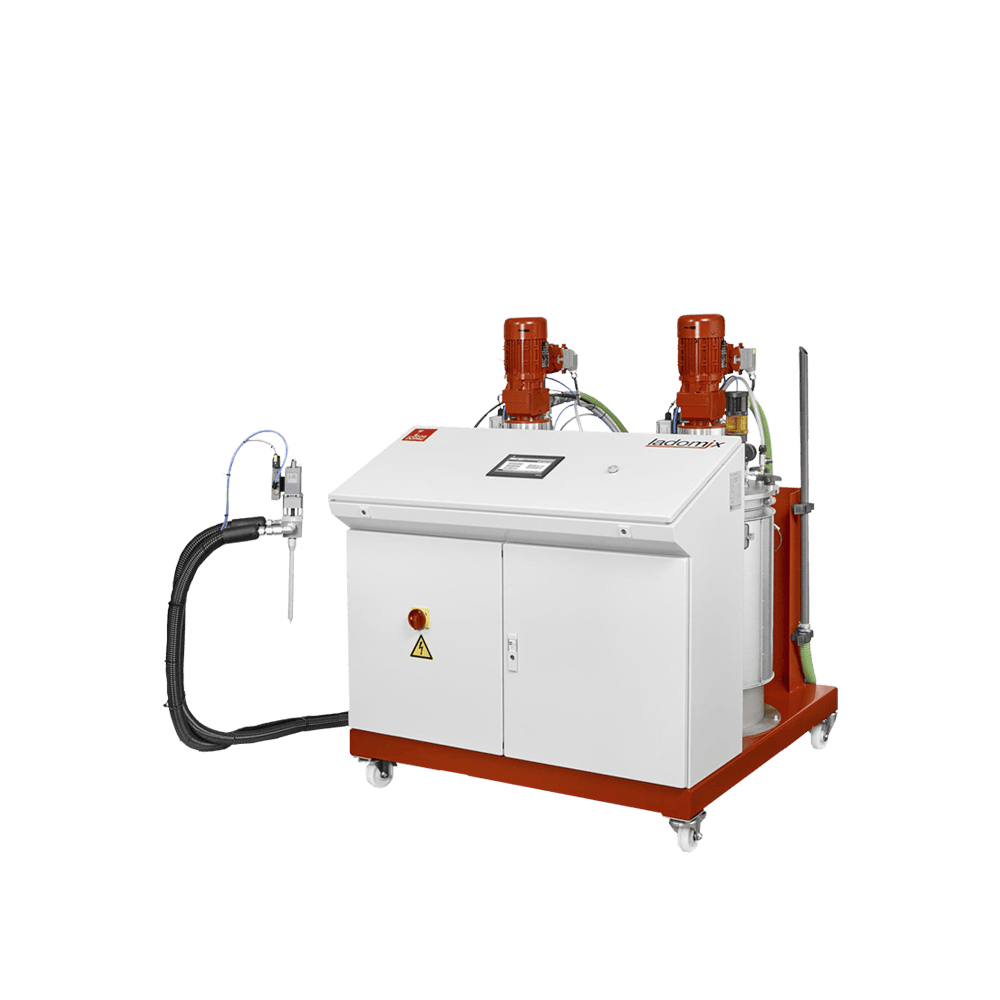

Ladomix : dispensing system for lamination; A system for the dispensing of adhesives in the packaging industry

The ladomix is a compact, mobile metering and mixing system for lamination in the packaging industry. It processes solvent-free, self-leveling two-component laminating adhesives made of polyurethane in a mixing ratio of 100:100 to 100:10. The material is then dispensed into the gap between the rollers of the laminating machine and applied onto the outer film of the packaging. Lastly, the outer film is glued to the inner film.

Material containers with the capacity of 60 l are used for material supply. These are automatically refilled either by means of vacuum using a suction set included in the standard version or by drum pumps, which are optional. The material container fill level is being continuously monitored by a set of analog rod probes. Metering is carried out by high-precision gear pumps installed inside the material container near the bottom and below the material level. These are driven by three-phase asynchronous motors. Both gear pumps are equipped with ovepressure protection in the standard version. Ladomix features a static mixing system as standard, consisting of a 2K valve with a static mixing tube made of plastic. The mixing tube can be disposed of inexpensively after the material has cured so that elaborate and environmentally harmful rinsing is effectively avoided.

Share

Skip to content

Skip to content