APPLICATIONS

Injection + Molding

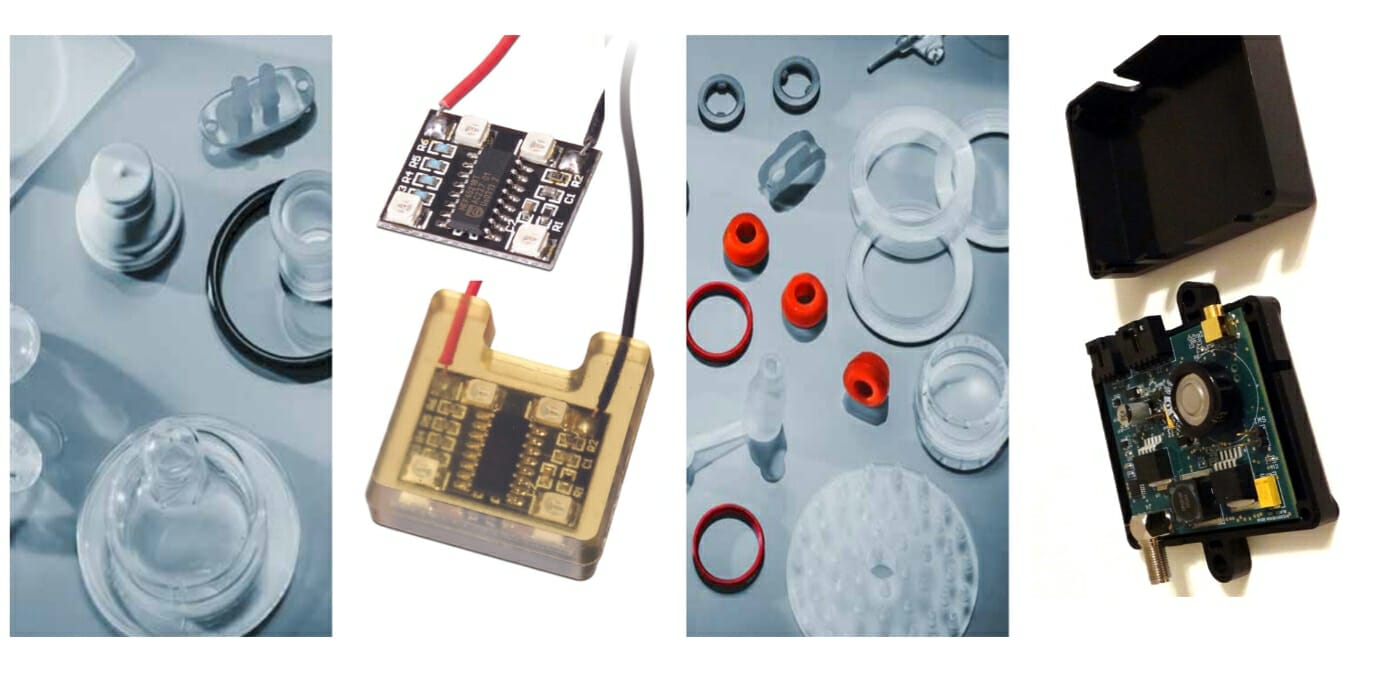

Injection and Molding

In the field of injection and molding, there usually are 3 types of material being used as silicone, hotmelt, and two-part mixed material.

Whereas for hotmelt adhesive material, usually special polyamide hotmelt adhesive is famous in the field of electronic application.

For two-part mixed material, sometimes called Reaction Injection Molding (RIM), The basis of the RIM process is usually a two-part, low viscosity polyurethane. The two parts – polyol and isocyanate – are precisely metered first and then homogeneously mixed (reaction). Subsequently, the material is injected at a low pressure (injection) into a closed mould, where it cures within a few minutes (moulding).

Our dispensing system ensures stability and reliability in continuous production – the prerequisite for your business success. Based on robust technology, we contribute to making your production a smooth and reliably running one – and this with even shorter setup times.

Skip to content

Skip to content