APPLICATIONS

Furniture and Wood Working

Furniture and Wood Working

Adhesive application systems for woodworking and furniture making, such as laminates, flooring, paneling, profiles wrapping, counter tops, self-assembly furniture and displays.

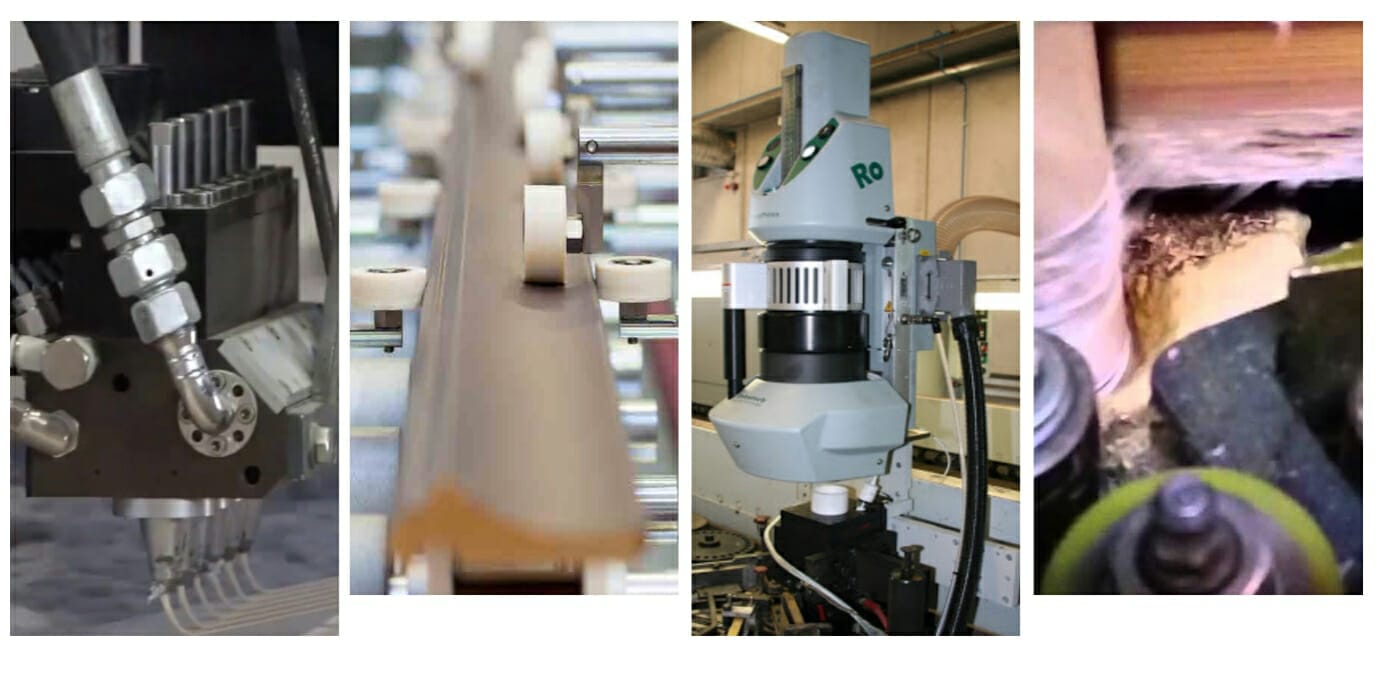

MDF, solid wood and plywood rely on a wide range of modern bonding and filling techniques. The perfect finish can only be achieved by highly accurate metering and uniform adhesive application using precision-engineered coating heads.

With Robatech technology, woodworking suppliers can achieve this level of perfection even in difficult laminating or wrapping processes. We combine unparalleled technical expertise of PUR, EVA, APAO hotmelt bonding processes with a comprehensive product range, including coating heads in different profile shapes for more accurate, even applications. Our FKV coating heads are characterized by a precise, high quality pattern and controlled application of adhesive. We also offer a special Wood Repair System (WRS) for enhancing the finish and value of engineered flooring and solid wood (parquet).

Our safe easy-to-operate products speed up production during

Our systems offer precise, even control of single and multi-bead applications, spray and coating processes.

- Panel laminating

- Edge banding

- Profile wrapping

- Wooden structure gluing using 1C PUR

- Counter top sealing

- Joint and fabric bonding

- Direct and post forming

Equipment for Woodworking application

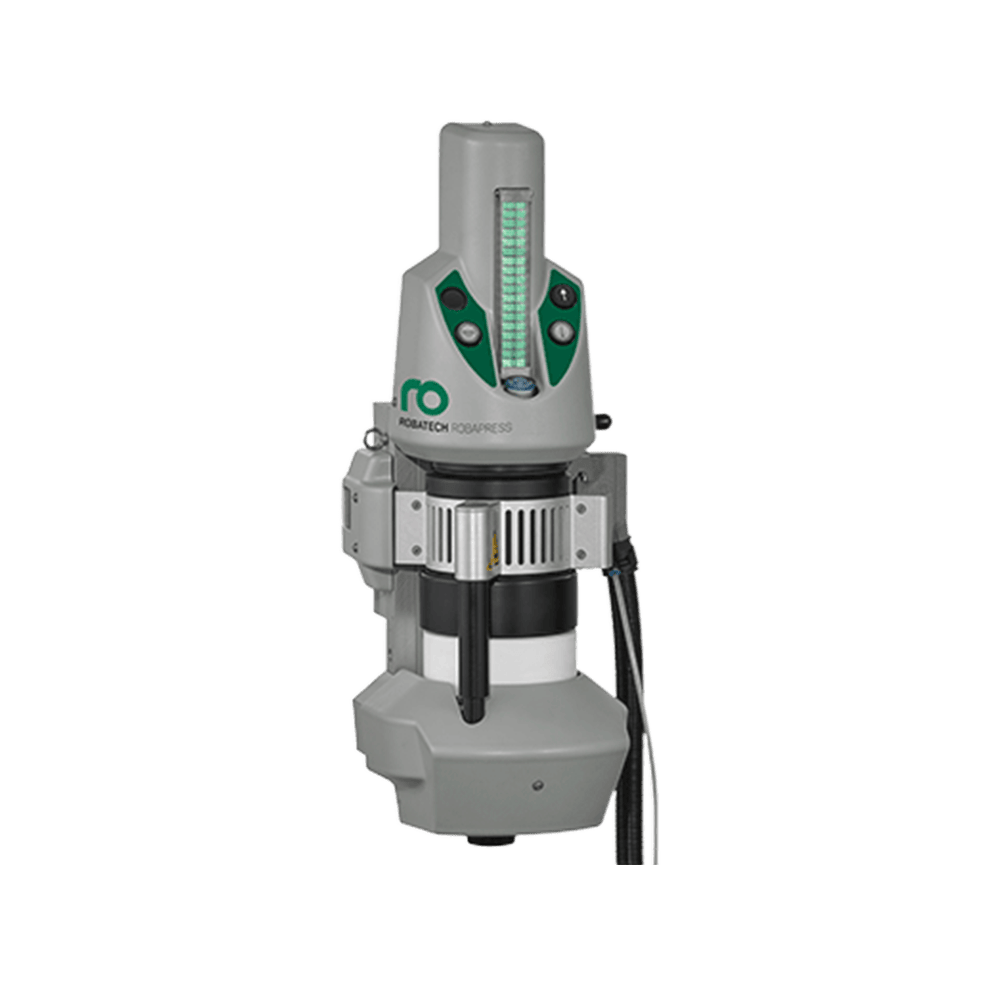

EdgePro

EdgePro is a coating head for edge banding of workpieces. The application head achieves high-quality gluing with uniform, repeatable adhesive application, and clean cut-off. EdgePro allows a quick and flexible adaptation to workpiece thickness, is easy to clean, and thus contributes to increased productivity.

FKV Coating Head for Profile Wrapping

The FKV is a wide slot-die coating head for continuous surface applications of thermoplastic or reactive hotmelts. It offers finely adjustable coating widths from 200–2,600 mm. (manual or motorized) and precisely controls the weight of the coat and reduce adhesive consumption

Roba 2 MOD

The RobaPUR 2 MOD adhesive melter is designed for processing different hot melt adhesives in block, granular, and cushion form. Particularly developed for demand-depending melting (Melt-on-Demand), it is suitable for processing almost all commercially available PUR adhesives as well as for PSA, EVA, and APAO hot melt adhesives.

JumboFlex

JumboFlex, Robatech’s big unit family for melting and delivery of large volumes of thermoplastic, non-reactive hot melt adhesives (EVA, PE, PSA, and APAO). Can be flexibly used for high-performance melting applications with unique, individual premelting solution for optimum processing of different forms of adhesive.

Skip to content

Skip to content