SPECIAL PRODUCTS

Silicone Liner

Silicone release

liner system

Shipping packaging has transformed in recent years due to an increasing demand for simple silicone release liners.

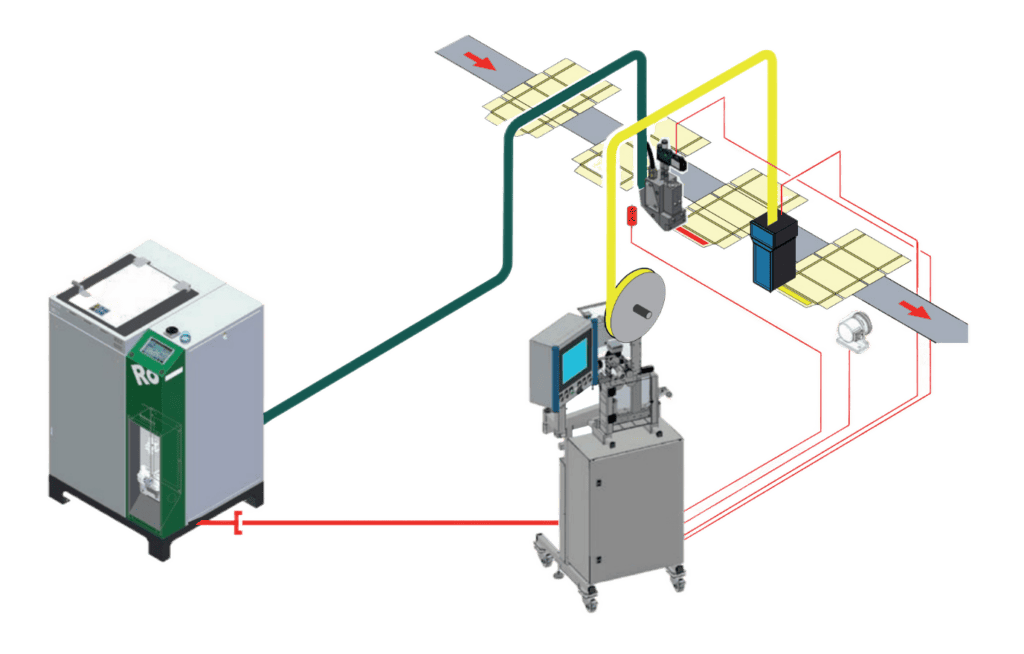

Robatech offers a straightforward and cost-effective solution together with a partner: hot melt adhesive application protected by a silicone paper. Flexibly adaptable to the packaging and system speed, the highest quality is achieved for a straightforward and reliable adhesive seal. The solution is suitable for new folding carton machines as well as for retrofitting existing systems.

A widespread solution for self-adhesive closures is double-sided adhesive tape. However, this is costly in procurement and further processing. Adhesive tape rolls have to be replaced at short intervals and thus cause constantly machine downtimes and increased operating effort. Furthermore, the silicone strip is tough to peel and can lead to dissatisfaction of the shipper later on.

Silicone Release Liner with Hot Melt Adhesive for Smooth Packaging

A narrow strip of PSA hot melt adhesive is applied using a coating nozzle to a cardboard flap, usually the lid of a packaging. Next, a silicon paper is positioned precisely on the glue trace using a dispenser for protection. The paper strip is usually slightly longer than the underlying adhesive application for easier removal. To ensure that the silicone paper strip can be applied precisely, the adhesive application must be very precise from start to finish. Robatech provides a clean adhesive cut-off even at high machine speeds of 200 m/min. If a tear strip is also applied to the packaging before the silicone release liner, correct positioning of the coating head is particularly important since it can otherwise remove the tear strip.

- › Precise and repeatable adhesive application with clean cut-off characteristics

- › Uniform adhesive application across the entire edge length and width of the workpiece

- › Improved productivity and production flexibility thanks to quick adaptation to new workpiece thicknesses

- › High availability and low cleaning effort due to integrated filter and the possibility to close the nozzle completely

Skip to content

Skip to content